16) Only install the tool when an easily accessible

and easily operable on/off switch is

incorporated in the air supply.

17) Take care that the tool exhaust air does not

cause problems or blow onto another person.

18) Never lay a tool down unless the working

attachment has stopped moving.

19) Always ensure that the forward/reverse switch

is in the desired position before starting

the tool.

20) Do not use sockets with excessive wear to the

input or output drives. Periodically check the

square drive on the air ratchet wrench. Make

sure the socket, extension bar, or other

attachment is securely fitted before

operating tool.

21) When loosening fasteners first ensure that

there is sufficient clearance behind the tool to

avoid hand entrapment. The tool will move

away from the threaded joint as the nut/bolt is

loosened and rides up the thread, moving the

tool with it.

Safety Rules For Pneumatic Tools

1) Inspect the air hose for cracks or other

problems. Replace the hose if worn.

2)

Never point an air hose at another person.

3)

Disconnect the tool when not in use, or before

performing service or changing accessories.

4)

Use proper hoses and fittings. Never use

quick-change couplings attached to the tool.

Instead, add a hose and coupling between the

tool and the air supply.

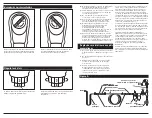

The recommended hook-up is shown in figure A.

Pneumatic tools operate on a wide range of air

pressures. For maximum efficiency and longer tool

life, the pressure of the air supplied to these tools

should not exceed the rated PSI at the tool when

the tool is running. Using a higher than rated

pressure will cause faster wear and drastically

shorten the tool's life. A higher air pressure can

also cause an unsafe condition.

The inside diameter of the hose should be

increased to compensate for unusually long air

hoses (over 25 feet). Minimum hose diameter

should be 3/8" I.D. and fittings should have the

same inside dimensions.

The use of air line lubricators and air line filters is

recommended to prevent water in the line that can

damage the tool. Drain the air tank daily. Clean the

air inlet filter screen on at least a weekly schedule

to remove accumulated dirt or other matter that

can restrict air flow.

The tool's air inlet used for connecting an air

supply has standard 1/4" NPT American thread.

Figure A

Forward/Reverse Switch

Rotate Forward/Reverse switch counter-clockwise

(Forward Position) for driving fastners.

Rotate Forward/Reverse switch clockwise (Reverse

Position) for removing fastners.

Air Regulator

Number above silver ball detent indicates air

regulator setting.

Turn number dial to lower number for decreased

power, or higher number for increased power.