Proper Use Of The Tool

Your new 3/8” Drive Air Ratchet Wrench is

designed for driving, tightening and loosening

threaded fasteners, usually nuts and bolts, when

fitted with a suitable socket.

Do not use the tool for any other purpose than that

specified without consulting the manufacturer or

the manufacturer’s authorized supplier. To do so

may be dangerous.

Never use the air ratchet wrench as a hammer to

dislodge or straighten cross threaded fasteners.

Never attempt to modify the tool for other uses.

Work Stations

Your air ratchet wrench should only be used as a

hand operated tool. It is always recommended that

the tool is used when standing with solid footing. It

can be used in other positions but before any such

use, the operator must be in a secure position

having a firm grip and footing and be aware that

when loosening fasteners the tool can move quite

quickly away from the fastener being undone. An

allowance must always be made for this rearward

movement so as to avoid the possibility of hand/

arm/body entrapment.

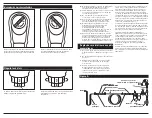

Putting Into Service

Air Supply

Use a clean lubricated air supply that will give a

measured air pressure at the tool of 90 psi/6.2 bar

when the tool is running with the throttle fully

depressed. Use recommended hose size and

length. It is recommended that the tool is

connected to the air supply as shown in figure A.

Do not connect the tool to the air line system

without incorporating an easy to reach and operate

air shut off valve. The air supply should be

lubricated. It is strongly recommended that an air

filter, regulator, lubricator (FRL) is used as shown in

figure A as this will supply clean, lubricated air at

the correct pressure to the tool. Details of such

equipment can be obtained from your supplier. If

such equipment is not used then the tool should be

lubricated by shutting off the air supply to the tool

and then depressurizing the line by squeezing the

throttle on the tool. Disconnect the air line and pour

into the intake bushing a teaspoon (5 ml) of a

suitable pneumatic motor lubricating oil, preferably

incorporating a rust inhibitor. Reconnect tool to air

supply and run tool slowly for a few seconds to

allow air to circulate the oil.

Lubricate tool daily if used frequently, or when it

starts to slow or lose power.

Operating Instructions

Securely fit the socket or attachment to the ratchet

wrench. Ensure that the forward/reverse switch is

in the correct position for tightening or loosening

the fastener.

The nut/bolt can then run down the thread by

depressing the throttle.

For loosening a joint the tool can be used in the

reverse sequence.

Using An Air Ratchet Wrench

1)

Read all instructions before using this tool. All

operators must be fully trained in its use and

aware of these safety rules.

2)

Do not exceed the maximum working air

pressure of 90 psi/6.2 bar.

3)

Use personal safety equipment.

4)

Use only compressed air at the recommended

conditions.

5)

If the tool appears to malfunction, remove from

use immediately and arrange for service and

repair.

6)

If the tool is used with a balancer or other

support device, ensure that it is fixed securely.

7)

Always keep hands away from the working

attachment fitted to the tool.

8)

The tool is not electrically insulated. Never use

the tool if there is any chance of it coming into

contact with live electricity.

9)

When using the tool, always adopt a firm

footing and/or position and grip the tool firmly

to counteract any forces or reaction forces that

may be generated while using the tool.

10) Use only correct spare parts. Do not improvise

or make temporary repairs.

11) Do not lock, tape, wire, etc. the on/off throttle

in the run position. The throttle must always be

free to return to the “off” position when it is

released.

12) Always shut off the air supply to the tool and

depress the throttle to release air from the feed

hose before fitting, adjusting or removing the

working attachment.

13) Check hoses and fittings regularly for wear.

Replace if necessary. Do not carry the tool by

its hose. Ensure the hand is removed from the

on/off tthrottle when carrying the tool with the

air supply connected.

14) Take care against entanglement of moving tool

parts with clothing, ties, hair, cleaning rags,

etc. This will cause the body to be drawn

towards the tool and can be very dangerous.

15) It is expected that users will adopt safe

working practices and observe all relevant

legal requirements when installing, using or

maintaining the tool.

Specifications

Especificaciones

Fiche technique

US

F

E

Average Air

Consumption

2.6 CFM (19 SCFM)

100% Usage

Promedio de

consumo de aire

2,6 CFM (19 SCFM)

Uso al 100%

Consommation

moyenne d’air

2,6 pi

3

/min (19 SCFM)

Usage à 100 %

Maximum RPM

165

Máximas RPM

165

Régime en tr/min

maximum

165

Max. Torque

60 ft-lb

Torsión máxima

60 lbs. pie

Tosion maximale

60 pi-lb

Air Inlet

1/4" NPT (F)

Entrada de aire

Rosca de 1/4 pul.

NPT (Hembra)

Entrée d’air

Taraudage de

6,35 mm NPT (F)

Weight

2.8 lbs.

Peso

2,8 lbs.

Poids

2,8 lb

Min. Hose Size

3/8"

Tamaño mínimo de

la manguera

3/8 pul.

Taille minimale du

tuyau

9,5 mm (3/8 po)

Square Drive

3/8”

Cuadrante

3/8 pul.

Carré

d’entraînement

9,5 mm (3/8 po)

Exhaust

360˚ Front

Escape

Delantero de 360°

Échappement

Avant sur 360°

Max. PSI

90

Lbs./pul

2

(PSI)

necesarias

90

Pression requise

en lb/po

2

90