26

•

Continue until oil fl owing from both bleed holes is free of air bubbles, (ensure that the reservoir is not starved of oil,

otherwise air will be drawn into the system introducing air bubbles in the oil stream).

•

When air free oil is fl owing from both bleed holes, operate the trigger and tighten the front bleed screw with an Allen

key. Release the trigger and tighten the rear bleed screw with an Allen key.

•

If necessary, top up the oil reservoir.

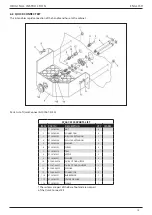

9.4 ALTERNATIVE PRIMING PROCEDURCE

CAUTION - CONNECT AIR SUPPLY (this causes the piston to bottom, allowing more priming oil into the tool).

CAUTION - All operations should be carried out on a clean bench, with clean hands, in a clean area.

CAUTION - Care MUST be taken, at all times, to ensure that no foreign matter enters the tool, or serious

damage may result.

Item numbers in bold refer to the General Assembly of Handle and Parts List on pages 21 and 22, item number 28* refers to

the General Assembly of Cabinet and Parts List on pages 23and 24.

•

Prior to starting the priming procedure, obtain a suitable container to collect excess oil.

•

Disconnect the air supply and undo the intensifi er Oil Reservoir Plug 28*.

•

Top up the reservoir in the cabinet with VG32 Hyspin® priming oil to a level of 20 mm (0.8”) below top of the reservoir.

If the oil hoses are changed, prime them before connecting, as follows:

•

Disconnect the air supply.

•

Place the oil tank in a higher position than the tool.

•

In that position, unscrew the Bleed Screws 18 and Washers 19 until the oil fl ows under gravity.

•

Once the oil starts to fl ow from one of the bleed holes, close it by tightening the screw. Wait until the oil fl ows from the

other bleed hole, then close this as well.

In other cases, prime as below:

•

CARE SHALL BE TAKEN TO ENSURE THAT THE BLEED HOLES ARE NOT DIRECTED TOWARDS THE OPERATOR OR OTHER

PERSONNEL.

•

Connect the tool to the air supply.

•

Keeping the trigger pressed, slightly loosen the Bleed Screw 18 (the closest to the front of the tool) until oil begins to

fl ow.

•

Keep the trigger pressed until there is no air in the oil, then tighten the Bleed Screw 18.

•

Release the trigger.

•

Repeat the last three steps, with intervals of several seconds, to ensure that clean oil circulates and all air is removed.

The hydraulic circuit for the pull side is now free of air. The following removes air from the hydraulic circuit on the return side.

•

Keep the tool connected to the air.

•

Without pressing the trigger (the return hydraulic circuit already has pressure), slightly loosen the Bleed Screw 18 from

the rear of the tool until oil begins to fl ow.

•

When there is no air in the oil, tighten the Bleed Screw 18.

• Operate

trigger.

•

Repeat the last three steps, with intervals of several seconds, to ensure that clean oil circulates and all air is removed.

•

Ensure that the oil reservoir is not starved of oil, otherwise air will be drawn into the system.

•

If necessary, refi ll the oil reservoir up to the level as indicated before.

To verify that the tool is correctly primed, measure the stroke. The piston stroke should be approximately 32mm and the

piston should always return fully.

E N G L I S H O R I G I N A L

I N S T R U C T I O N

Summary of Contents for 07287

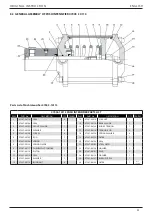

Page 22: ...21 8 2 GENERAL ASSEMBLY OF CABINET 07287 03200 ORIGINAL INSTRUCTION ENGLISH...

Page 34: ...3 1 1 1 STANLEY Engineered Fastening ISO 11148 1 2...

Page 35: ...4 1 3 1 4 1 5 1 6...

Page 36: ...5 1 7 1 8 1 9 7 102 PSI 100 C 212 F...

Page 38: ...7 2 2 1...

Page 41: ...10 4 2 OPTION 1 OPTION 2...

Page 50: ...19 30 220 C CO2 7 13...

Page 51: ...20 8 8 1 07287 01000 07287 01300 3 07287 01500 5...

Page 53: ...22 8 2 07287 03200...

Page 58: ...27 18 19 18 19 9 4 21 22 28 23 24 28 VG32 Hyspin 20 0 8 18 19 18 18 18 18 32...

Page 59: ...28 10 10 1 10 15 19 27 28 19 19 19 19 11 27 29 11 27 29 Avdel...

Page 63: ...32...

Page 84: ...21 8 2 OP ENITO SASTAVLJANJE ORMARI A 07287 03200 PRIJEVOD IZVORNIH UPUTA HRVATSKI...

Page 114: ...21 8 2 CELKOV SESTAVA SK N 07287 03200 P EKLAD Z ORIGIN LN CH POKYN ESKY...

Page 145: ...22 8 2 ANSAMBLUL GENERAL AL UNIT II 07287 03200 ROM N TRADUCERE A INSTRUC IUNILOR ORIGINALE...

Page 155: ...32 ROM N TRADUCERE A INSTRUC IUNILOR ORIGINALE...

Page 177: ...22 8 2 A SZEKR NY 07287 03200 LTAL NOS SSZESZEREL SE MAGYAR FORD T S AZ ANGOL EREDETIB L...

Page 187: ...32 MAGYAR FORD T S AZ ANGOL EREDETIB L...

Page 208: ...21 8 2 CELKOV ZOSTAVA SKRINE 07287 03200 PREKLAD Z ORIGIN LNYCH POKYNOV SLOVEN INA...

Page 238: ...21 8 2 SPLO NI SKLOP OMARICE 07287 03200 PREVOD IZVIRNIH NAVODIL SLOVEN INA...

Page 250: ...3 1 1 1 STANLEY Engineered Fastening ISO 11148...

Page 251: ...4 1 2 1 3 1 4 1 5 1 6...

Page 252: ...5 1 7 1 8 1 9 7 102 100 C 212 F...

Page 254: ...7 2 2 1...

Page 257: ...10 4 2 1 2...

Page 266: ...19 220 C CO2 7 13...

Page 267: ...20 8 8 1 07287 01000 07287 01300 3 07287 01500 5...

Page 269: ...22 8 2 07287 03200...

Page 274: ...27 18 19 18 19 9 4 21 22 28 23 24 28 VG32 Hyspin 20 0 8 18 19 18 18 18 18 32...

Page 275: ...28 10 10 1 10 15 19 27 28 19 19 19 19 11 27 29 11 27 29 Avdel...

Page 279: ...32...

Page 282: ...3 1 1 1 STANLEY Engineered Fastening ISO 1 2 1 3...

Page 283: ...4 1 4 1 5 1 6 1 7 1 8 1 9...

Page 284: ...5...

Page 285: ...6 2 2 1 ISO ISO LWA A kWA A A LpA kpA C LpC kpC ISO ISO ahd EN...

Page 286: ...7 2 2...

Page 289: ...10 4 2...

Page 290: ...11 5 5 1 V 07287 5 2...

Page 292: ...13 Hemlok Maxlok Avtainer Avdelok Monobolt HEMLOK o SET 5 4...

Page 293: ...14 6 6 1 M M M M M 6 2 1 2 3 4 5 10 11 10 8 9 7 9 6 5...

Page 294: ...15 6 3...

Page 295: ...16 7 7 1 7 2 EP 7 3...

Page 296: ...17 7 4 EP 7 5 7 6 7 7 7 8 7 9...

Page 297: ...18 7 10 7 11 MOLY LITHIUM GREASE EP 3753 7 12 7 13...

Page 298: ...19 8 8 1...

Page 299: ...20 o o o o o o...

Page 300: ...21 07287 03200 8 2...

Page 301: ...22 T...

Page 302: ...23 07005 10113 8 3...

Page 303: ...24 07005 10112 8 4 o o...

Page 304: ...25 9 9 1 Hyspin VG HYSPIN VG 32 9 2 PVC 9 3 Hyspin VG Allen Allen...

Page 305: ...26 9 4 Hyspin VG...

Page 306: ...27 10 10 1 Avdel...

Page 330: ...21 8 2 SKAPJA 07287 03200 VISP R G MONT A TULKOJUMS NO ROKASGR MATAS ORI IN LVALODAS LATVIE U...

Page 360: ...21 8 2 BENDRASIS SPINTOS 07287 03200 MAZGAS ORIGINALO INSTRUKCIJ VERTIMAS LIETUVI KAI...

Page 390: ...21 8 2 KOOSTEJOONIS KAPP 07287 03200 ORIGINAALJUHENDI T LGE EESTI KEEL...

Page 402: ...3 1 1 1 STANLEY Engineered Fastening ISO 11148 1 2...

Page 403: ...4 1 3 1 4 1 5 1 6...

Page 404: ...5 1 7 1 8 1 9 7 bar 102 psi 100 C 212 F...

Page 406: ...7 2 2 1...

Page 409: ...10 4 2 1 2...

Page 418: ...19 7 12 EP 3753 30ml 220 C CO2 Halon 7 13...

Page 419: ...20 8 8 1 07287 01000 07287 01300 3 M 07287 01500 5 M...

Page 421: ...22 8 2 07287 03200...

Page 426: ...27 18 19 18 19 9 4 21 22 28 23 24 28 VG32 Hyspin 20mm 0 8 18 19 18 18 18 18 32mm...

Page 427: ...28 10 10 1 10 15 19 27 28 19 19 19 19 11 27 29 11 27 29 Avdel...

Page 431: ...32...

Page 452: ...21 8 2 B LMEN N GENEL KURULUMU 07287 03200 OR J NAL KILAVUZDAN EV R T RK E...