16

7. SERVICING THE TOOL

Regular servicing should be carried out and a comprehensive inspection performed annually or every 500000 cycles,

whichever is sooner

.

CAUTION - Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals

may weaken the materials used in these parts.

CAUTION - Before maintenance, remove any dangerous substances that may have accumulated due to work

processes.

CAUTION - The employer is responsible for ensuring that tool maintenance instructions are given to the

appropriate personnel.

CAUTION - The operator should not be involved in maintenance or repair of the tool unless properly trained.

CAUTION - The tool shall be examined regularly for damage and malfunction.

CAUTION - Read Safety Instructions on page 4 to 6.

7.1 DAILY SERVICING

•

Daily, before use or when fi rst putting the tool into service, pour a few drops of clean, light lubricating oil into the

air inlet of the tool if no lubricator is fi tted on air supply. If the tool is in continuous use, the air hose should be

disconnected from the main air supply and the tool lubricated every two to three hours.

•

Check for air leaks. If damaged, hoses and couplings should be replaced by new items.

•

If there is no fi lter on the pressure regulator, bleed the air line to clear it of accumulated dirt or water before connecting

the air hose to the tool. If there is a fi lter, drain it.

•

Check that the nose equipment is correct.

•

Check oil level in intensifi er’s reservoir. If necessary top up with the prescribed priming oil.

7.2 WEEKLY SERVICING

•

Dismantle and clean nose assembly, with special attention to the jaws. Lubricate with Moly Lithium grease EP 3753

before assembling.

•

Check for oil leaks and air leaks in the air supply hose and fi ttings.

For all servicing we recommend the use of the service kit (part number 07900-02670).

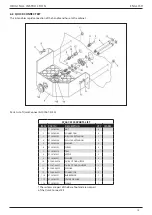

7.3 SERVICE KIT

Service Kit 07900-02670

Part Number

Description

Qty

07900-00589

SPREADER

1

07900-00590

PUSHER

1

07900-00591

BULLET

1

07900-00592

GAUGE

1

E N G L I S H O R I G I N A L

I N S T R U C T I O N

Summary of Contents for 07287

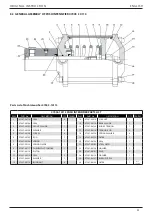

Page 22: ...21 8 2 GENERAL ASSEMBLY OF CABINET 07287 03200 ORIGINAL INSTRUCTION ENGLISH...

Page 34: ...3 1 1 1 STANLEY Engineered Fastening ISO 11148 1 2...

Page 35: ...4 1 3 1 4 1 5 1 6...

Page 36: ...5 1 7 1 8 1 9 7 102 PSI 100 C 212 F...

Page 38: ...7 2 2 1...

Page 41: ...10 4 2 OPTION 1 OPTION 2...

Page 50: ...19 30 220 C CO2 7 13...

Page 51: ...20 8 8 1 07287 01000 07287 01300 3 07287 01500 5...

Page 53: ...22 8 2 07287 03200...

Page 58: ...27 18 19 18 19 9 4 21 22 28 23 24 28 VG32 Hyspin 20 0 8 18 19 18 18 18 18 32...

Page 59: ...28 10 10 1 10 15 19 27 28 19 19 19 19 11 27 29 11 27 29 Avdel...

Page 63: ...32...

Page 84: ...21 8 2 OP ENITO SASTAVLJANJE ORMARI A 07287 03200 PRIJEVOD IZVORNIH UPUTA HRVATSKI...

Page 114: ...21 8 2 CELKOV SESTAVA SK N 07287 03200 P EKLAD Z ORIGIN LN CH POKYN ESKY...

Page 145: ...22 8 2 ANSAMBLUL GENERAL AL UNIT II 07287 03200 ROM N TRADUCERE A INSTRUC IUNILOR ORIGINALE...

Page 155: ...32 ROM N TRADUCERE A INSTRUC IUNILOR ORIGINALE...

Page 177: ...22 8 2 A SZEKR NY 07287 03200 LTAL NOS SSZESZEREL SE MAGYAR FORD T S AZ ANGOL EREDETIB L...

Page 187: ...32 MAGYAR FORD T S AZ ANGOL EREDETIB L...

Page 208: ...21 8 2 CELKOV ZOSTAVA SKRINE 07287 03200 PREKLAD Z ORIGIN LNYCH POKYNOV SLOVEN INA...

Page 238: ...21 8 2 SPLO NI SKLOP OMARICE 07287 03200 PREVOD IZVIRNIH NAVODIL SLOVEN INA...

Page 250: ...3 1 1 1 STANLEY Engineered Fastening ISO 11148...

Page 251: ...4 1 2 1 3 1 4 1 5 1 6...

Page 252: ...5 1 7 1 8 1 9 7 102 100 C 212 F...

Page 254: ...7 2 2 1...

Page 257: ...10 4 2 1 2...

Page 266: ...19 220 C CO2 7 13...

Page 267: ...20 8 8 1 07287 01000 07287 01300 3 07287 01500 5...

Page 269: ...22 8 2 07287 03200...

Page 274: ...27 18 19 18 19 9 4 21 22 28 23 24 28 VG32 Hyspin 20 0 8 18 19 18 18 18 18 32...

Page 275: ...28 10 10 1 10 15 19 27 28 19 19 19 19 11 27 29 11 27 29 Avdel...

Page 279: ...32...

Page 282: ...3 1 1 1 STANLEY Engineered Fastening ISO 1 2 1 3...

Page 283: ...4 1 4 1 5 1 6 1 7 1 8 1 9...

Page 284: ...5...

Page 285: ...6 2 2 1 ISO ISO LWA A kWA A A LpA kpA C LpC kpC ISO ISO ahd EN...

Page 286: ...7 2 2...

Page 289: ...10 4 2...

Page 290: ...11 5 5 1 V 07287 5 2...

Page 292: ...13 Hemlok Maxlok Avtainer Avdelok Monobolt HEMLOK o SET 5 4...

Page 293: ...14 6 6 1 M M M M M 6 2 1 2 3 4 5 10 11 10 8 9 7 9 6 5...

Page 294: ...15 6 3...

Page 295: ...16 7 7 1 7 2 EP 7 3...

Page 296: ...17 7 4 EP 7 5 7 6 7 7 7 8 7 9...

Page 297: ...18 7 10 7 11 MOLY LITHIUM GREASE EP 3753 7 12 7 13...

Page 298: ...19 8 8 1...

Page 299: ...20 o o o o o o...

Page 300: ...21 07287 03200 8 2...

Page 301: ...22 T...

Page 302: ...23 07005 10113 8 3...

Page 303: ...24 07005 10112 8 4 o o...

Page 304: ...25 9 9 1 Hyspin VG HYSPIN VG 32 9 2 PVC 9 3 Hyspin VG Allen Allen...

Page 305: ...26 9 4 Hyspin VG...

Page 306: ...27 10 10 1 Avdel...

Page 330: ...21 8 2 SKAPJA 07287 03200 VISP R G MONT A TULKOJUMS NO ROKASGR MATAS ORI IN LVALODAS LATVIE U...

Page 360: ...21 8 2 BENDRASIS SPINTOS 07287 03200 MAZGAS ORIGINALO INSTRUKCIJ VERTIMAS LIETUVI KAI...

Page 390: ...21 8 2 KOOSTEJOONIS KAPP 07287 03200 ORIGINAALJUHENDI T LGE EESTI KEEL...

Page 402: ...3 1 1 1 STANLEY Engineered Fastening ISO 11148 1 2...

Page 403: ...4 1 3 1 4 1 5 1 6...

Page 404: ...5 1 7 1 8 1 9 7 bar 102 psi 100 C 212 F...

Page 406: ...7 2 2 1...

Page 409: ...10 4 2 1 2...

Page 418: ...19 7 12 EP 3753 30ml 220 C CO2 Halon 7 13...

Page 419: ...20 8 8 1 07287 01000 07287 01300 3 M 07287 01500 5 M...

Page 421: ...22 8 2 07287 03200...

Page 426: ...27 18 19 18 19 9 4 21 22 28 23 24 28 VG32 Hyspin 20mm 0 8 18 19 18 18 18 18 32mm...

Page 427: ...28 10 10 1 10 15 19 27 28 19 19 19 19 11 27 29 11 27 29 Avdel...

Page 431: ...32...

Page 452: ...21 8 2 B LMEN N GENEL KURULUMU 07287 03200 OR J NAL KILAVUZDAN EV R T RK E...