2

Standard Pump Operating Instructions and Parts Manual (OIPMS0611)

Standard Pump Operating Instructions and Parts Manual (OIPMS0611)

Description

Standard’s Drum Pumps are designed to transfer a variety of

materials from 55 gallon drums and tanks . Standard Pump

offers several different pumps, each designed for specific

applications. Before operating, please confirm that the pump’s

materials of construction are suitable for the application.

Unpacking

Cartons should be handled with care to avoid damage from

dropping, etc . After unpacking, inspect carefully for any

damage that may have occurred during transit. Check for

loose, damaged or missing parts .

General Safety Information

The responsibility for safe assembly, installation, and operation

ultimately rests with the operator. Read and understand ALL

safety precautions and operating instructions before operation .

Careless pump operation can result in serious injury .

1. Before operating the pump, read and understand these

operating instructions .

2. The operator should wear suitable protective clothing

including the following: face mask, safety shield or

goggles, gloves, apron, and safety shoes.

3. Before operating, verify the materials being pumped are

compatible with the pump’s “wetted components.”

4. All Federal, State, and local safety codes should be

followed .

5. Verify that the motor voltage corresponds to proper

electrical supply .

6. Before plugging motor into power supply, make sure the

motor switch is in the OFF position.

7 . Before operation, confirm all pump connections are

properly tightened.

8. First pump clean water in order to familiarize yourself with

the pump’s operation, flow rate, discharge pressure and

motor speed .

9. Before starting the pump, confirm the discharge hose is

securely fastened to the receiving vessel in order to prevent

splashing.

10 . Never leave pump unattended during operation .

11. Do not submerge the motor in any liquid.

12. When finished using the pump, flush the pump by

pumping water or an appropriate cleaning solution . Do not

use flammable or combustible cleaning solutions .

13. Never carry the motor by the power cord.

Assembly

1. Remove the pump and motor from packaging.

2 . Inspect all contents for damage .

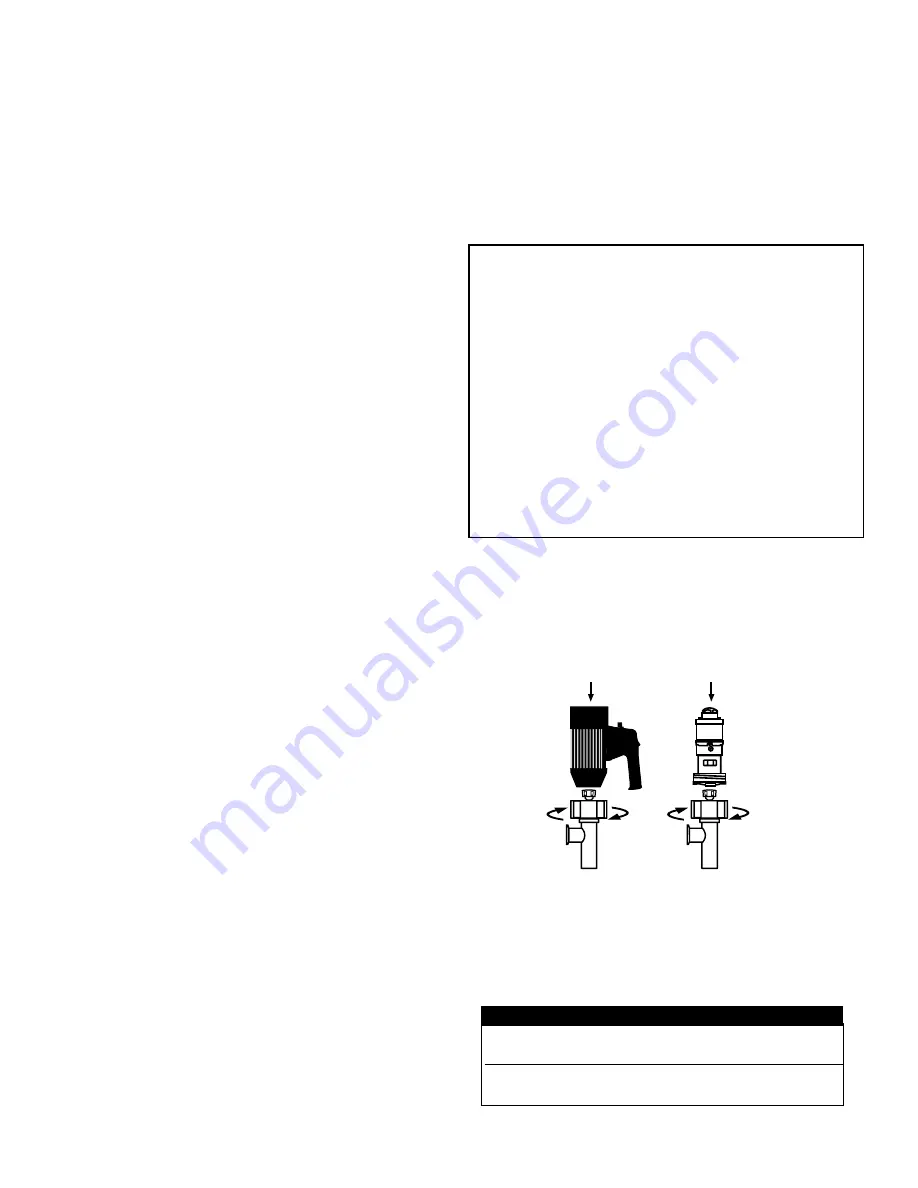

3. Couple the motor to the pump tube by using the Hex Nut

(see Figure 1) .

4. It is recommended to thoroughly clean and sanitize models

SP-8100 & SP-8200 before operation .

5. First pump clean water in order to familiarize yourself with

the pump’s operation, flow rate, discharge pressure and

motor speed .

Standard Pump

Sanitary Pump Models:

SP-8100, SP-8200, SP-8800, SP-8900, SP-800SR & SP-800DD

SP-8100 & SP-8200 SERIES

Note:

Flow rates are based on water. As viscosity increases, the flow

rate will decrease .

Specifications

Models SP-8100 & SP-8200

Maximum Liquid

Temperature . . . . . . . . . . . . . . . . . . . .175º

F (79

º C)

Pump Type . . . . . . . . . . . . . . . . . . . . . . .Centrifugal

Pump Speed . . . . . . . . . . . . . . . . . . . . .10,000 RPM

Max. Flow Rate

SP-8100

. . . . . . . . . . . . . . . . . . 32 GPM (121 LPM)

SP-8200 . . . . . . . . . . . . . . . . . . . . 15 GPM (57 LPM)

Max. Discharge Pressure SP-8100

. . . . . . . . . . . . . . . . . . . . . . . . 16 psi (1,1 bar)

SP-8200 . . . . . . . . . . . . . . . . . . . . . . . . 32 psi (2,2 bar)

Wetted Materials . . . . . . . . . . . .SS 316, Buna & Teflon

Immersion Length

. . . . . . . . . . .47" (1200 mm) (Tanks)

39

" (1000 mm) (Drums & Barrels)

Discharge Port

. . . . . . . . . . . . . . . . . . . .1 .0"

(25 mm) Hose Barb &

1 .5" (38 mm) Tri-Clamp

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SP-280P Series, SP-ENC Series,

SP-A1FP, SP-A2 Series

Electric

Air

Figure 1

Model

Air Connection

Consumption

SP-A1FP

.125" (3,2 mm)

28 CFM @ 90 psi

13 .2 L/sec @ 6,2 bar

SP-A2L

.25" (6,3 mm)

28 CFM @ 90 psi

SP-A2

13 .2 L/sec @ 6,2 bar

Note:

For optimum performance make sure proper size air

lines are installed .