12

Standard Pump Operating Instructions and Parts Manual (OIPMS0611)

7

. Once the pump is fully assembled and all connections are

fastened, insert the pump into the drum or tank. Pump can

be suspended from hoisting system using a pump hanger

(P/N: 8430) .

8. It is recommended to attach a suitable hose or pipe to the

pump discharge.

9. If you opt to use a hose, fasten the hose to the hose

barb with a suitable hose clamp that exceeds the pump

discharge pressure.

Make sure the hose meets the pump

discharge pressure requirements (SP-800-751

or SP-800-1851=87 psi (6 bar)) / (SP-800-752=174 psi (12,1 bar)).

It is recommended to use a hose that is rated 4 x the pump

discharge pressure. Ex: 87 x 4= 348 psi (24,3 bar).

Maintenance

DISASSEMBLY / CLEANING PROCEDURES (SP-800SR &

SP-800DD)

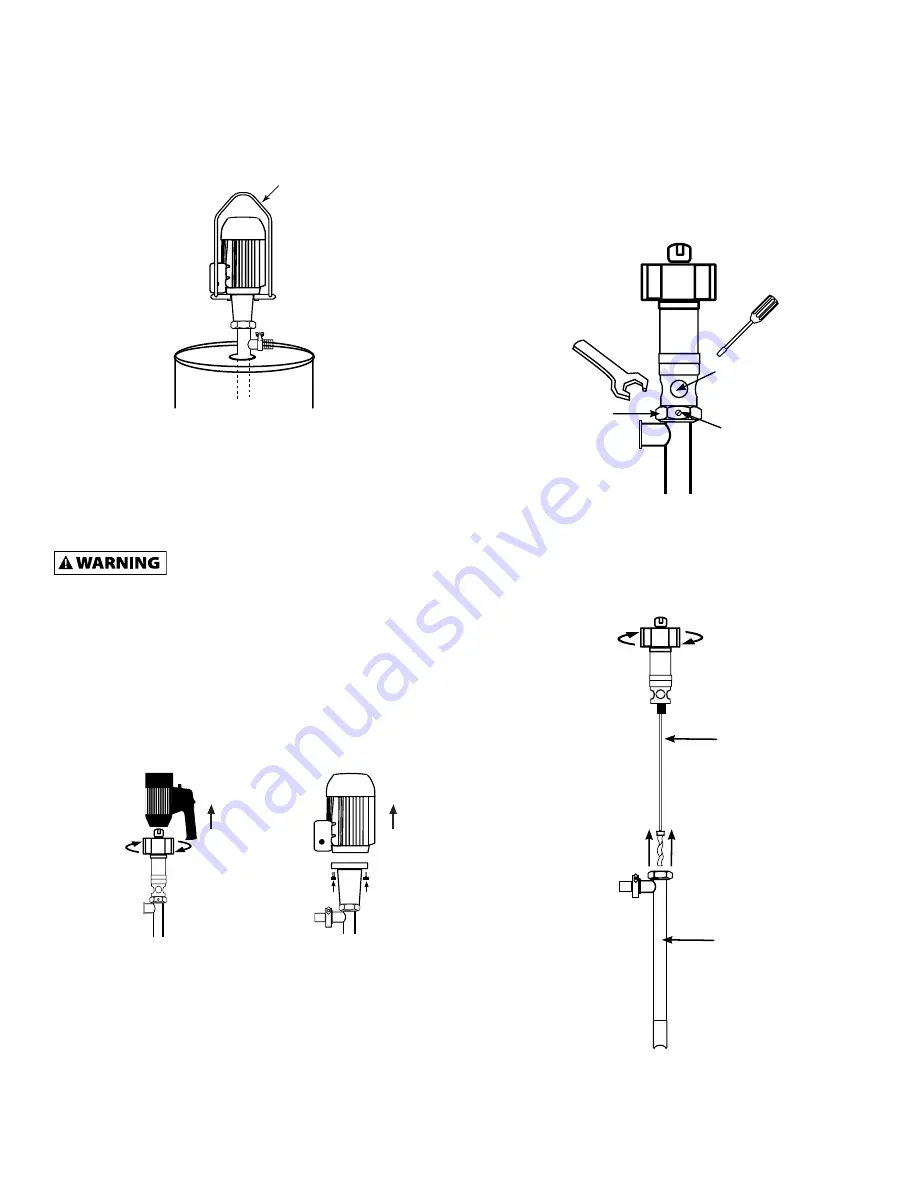

1 . Remove motor from pump tube . For models SP-800SR:

loosen Hex Nut in clockwise rotation (see Figure 3). For

models SP-800DD: loosen (4) bolts that attach the pump to

the motor (see Figure 4).

2. Loosen set screw on side of Hex Nut (see Figure 5).

3. Place a screwdriver (or similarly shaped object) in the

mechanical seal inspection port (see Figure 5).

4. Use a large wrench to loosen the Hex Nut while

simultaneously holding the screwdriver in the seal

inspection port (see Figure 5) .

5. Once the Hex Nut is loosened, remove the outer tube from

the drive shaft assembly (see Figure 6).

Figure 5

Mechanical Seal

Inspection Port

Set Screw

Hex Nut

Outer Tube

Assembly

Drive Shaft

Assembly

Figure 6

P/N: 8430

Figure 4

NOTE:

Remove 4 bolts

from motor flange .

Figure 3

NOTE:

Remove motor

by turning hex nut

clockwise