11

en

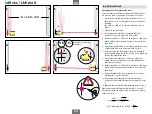

8.2 Horizontal check

Checking the horizontal laser line level

Be sure to adhere as closely as possible to the orientation

of the unit as shown.

1. Place the LAR 160 / LAR 160 G on a horizontal surface

or on a tripod at a distance of at least 10 m (50’) from a

wall, with the operator panel towards the wall.

2. Switch the laser unit on and wait until it has auto

matically levelled itself.

3. Mark the centre of the visible laser line on the wall

– measurement 1 (point 1). A receiver can also be used.

4. Rotate the entire laser unit through 90° without altering

the height of the laser (i.e. do not change the tripod

height). Allow the unit to level itself again.

5. Mark the centre of the laser line on the wall (point 2).

6. Repeat steps 4 and 5 twice to obtain points 3 and 4.

7. If the differences between the four control points are

less than 2 mm (1/8”) for a distance of 10 m (50 ‘), the

unit is within its permitted tolerance of ± 0.1 mm/m

(± 18” over 100ft). Here points 1 and 3 correspond to

the unit’s x-axis and points 2 and 4 to its y-axis.

1

1

8.1 Checking Accuracy

The STABILA LAR 160/ LAR 160 G rotation laser has been

designed for construction sites and has left our factory

in a correctly adjusted condition. As with all precision

instruments, you should regularly check the calibration

accuracy of the unit. Before starting work each day, and

particularly if the unit has been exposed to heavy shocks

or vibrations, a check of the calibration should be

carried out.

Horizontal check

Vertical check

10 m

≤ 2 mm

50'

≤ 1/8”

10 m / 50’

Maximum permissible

difference: