SCF-050 Manual

30

When burning corn, wheat, rye & Distiller’s Grain pellets the burn pot should be

“BALANCED

”. This means the fuel that is being augered into the burn pot rapidly turns

into glowing coals. If you see a lot of unburned fuel in the pot, an adjustment may be

needed. In an unbalanced pot the corn, wheat or rye will quickly stick together and

prevent the proper flow of combustion air. The pot will overload and the fire will go out.

When burning pellets or Cherry Pits make sure to check for the formation of creosote in

the unit and venting system. Constantly running the Furnace on a low setting with too

much combustion air may cause creosote to form. Burn pot temperatures can be “too

cool” when burning on low with too much draft. Once the damper is adjusted for your

installation, it should not be necessary to make any further adjustments to the damper.

The combustion air is automatically increased every time the feed rate is advanced on the

control board. If you notice a difference in the operation of the Furnace, first check to see

if the Furnace needs cleaning. Then check to see if there is a change in the fuel you are

burning. The moisture content of your Grains may be too high or the quality of the pellets

you are burning may have changed. Break-in requires the burning of 15 bushel of fuel or

15 bags of pellets or a continuous burn for two weeks.

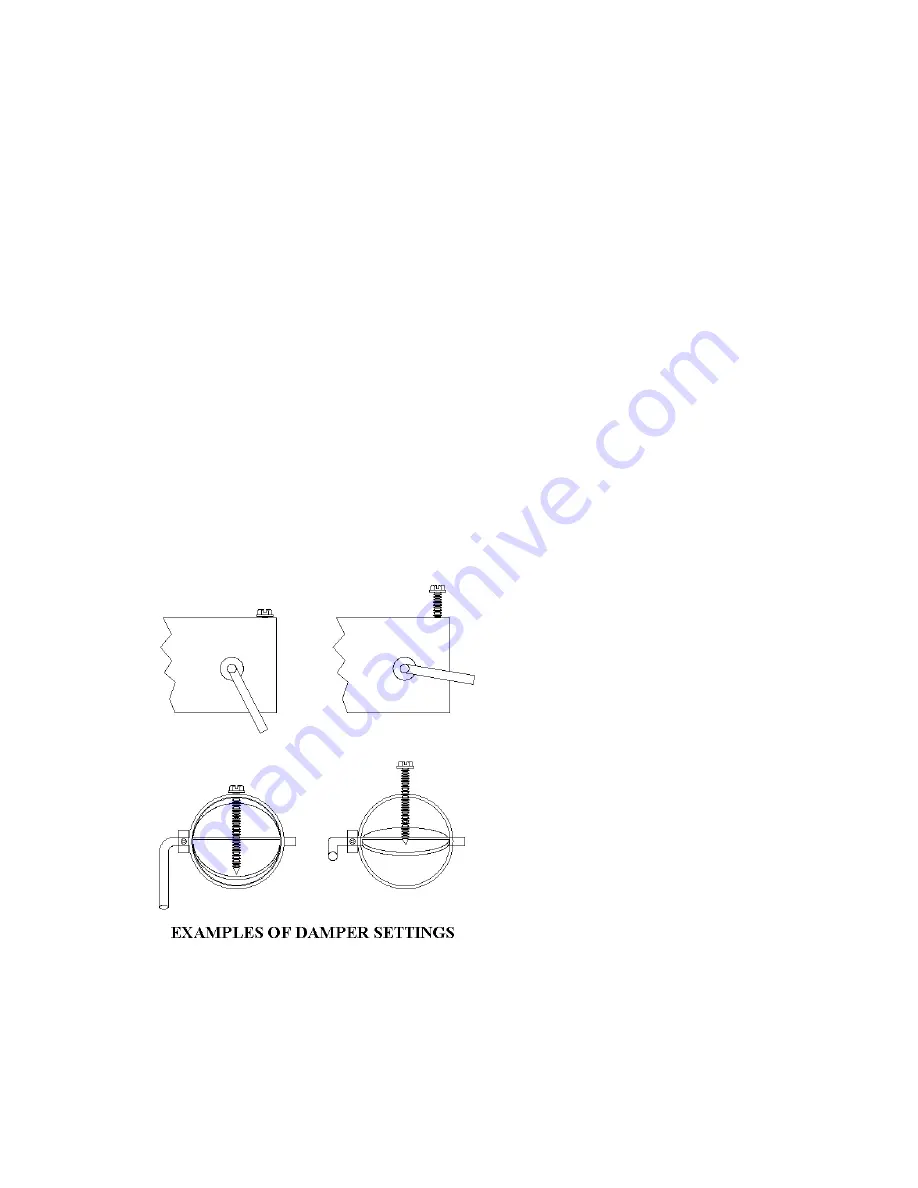

The setscrew is a useful tool in

making adjustments to the Air

Intake damper

.

Adjust the

damper by turning the screw

one

half turn

clockwise and place

the damper blade against the

screw. Wait 10 minutes to allow

the burn to adjust to the new

setting. Making too many

changes in a short period of time

will not allow for an accurate

adjustment.

Figure 15