Summary of Contents for ACTYON 2008.07

Page 2: ...0 2 undefined 0000 00 GENERAL ...

Page 3: ...0 3 GENERAL undefined 0000 00 4110 01 GENERAL GENERAL 1 DIMENSIONS ...

Page 4: ...0 4 undefined 0000 00 GENERAL 2 SPECIFICATIONS ...

Page 5: ...0 5 GENERAL undefined 0000 00 ...

Page 12: ...0 12 undefined 0000 00 GENERAL 6 JACK UP POINTS ...

Page 14: ...0 14 undefined 0000 00 GENERAL 8 ELECTRIC COMPONENTS AND LAYOUT 1 Wiring Harness Arrangement ...

Page 15: ...0 15 GENERAL undefined 0000 00 2 Components Locator ...

Page 16: ...0 16 undefined 0000 00 GENERAL 8 STANDARD BOLTS SPECIFICATIONS ...

Page 20: ......

Page 22: ...01 4 undefined 0000 00 ENGINE GENERAL 3 FRONT VIEW 4 FAN BELT ...

Page 59: ...01 41 ENGINE GENERAL undefined 0000 00 16 STANDARD BOLTS SPECIFICATIONS ...

Page 69: ...02 10 undefined 1212 01 ENGINE ASSEMBLY 3 TIGHTENING TORQUE ...

Page 70: ...02 11 ENGINE ASSEMBLY undefined 1212 01 ...

Page 71: ...02 12 undefined 1212 01 ENGINE ASSEMBLY ...

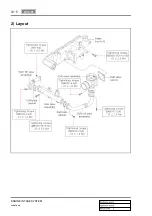

Page 75: ...04 6 undefined 2313 01 ENGINE INTAKE SYSTEM 2 Layout ...

Page 79: ...04 10 undefined 2313 01 ENGINE INTAKE SYSTEM 2 AIR FLOWS 1 Work Flow of Intake System ...

Page 83: ...05 6 undefined 1913 01 ENGINE EXHAUST SYSTEM 2 Exhaust Gas Flows ...

Page 118: ...10 5 CRUISE CONTROL SYSTEM undefined 8510 23 2 CIRCUIT DIAGRAM 1 Configuration ...

Page 126: ...01 5 ENGINE ASSEMBLY undefined 1114 00 Right Side View Left Side View ...

Page 129: ...01 8 undefined 1114 00 ENGINE ASSEMBLY 3 TIGHTENING TORQUE ...

Page 130: ...01 9 ENGINE ASSEMBLY undefined 1114 00 ...

Page 131: ...01 10 undefined 1114 00 ENGINE ASSEMBLY ...

Page 139: ......

Page 142: ...02 8 undefined 1881 09 ENGINE FUEL SYSTEM 2 FUEL FLOW OF D20DT EURO 4 ENGINE ...

Page 150: ...06 2 undefined 0000 00 ENGINE COOLING SYSTEM ...

Page 153: ...06 5 ENGINE COOLING SYSTEM undefined 0000 00 1 Structure of Water Pump for D20DT Engine ...

Page 154: ......

Page 155: ...NO DATA ...

Page 170: ...09 5 CRUISE CONTROL SYSTEM undefined 8510 23 2 CIRCUIT DIAGRAM 1 Configuration ...

Page 178: ...01 5 ENGINE ASSEMBLY undefined 1113 01 2 G23D ENGINE ASSEMBLY Front View Rear View ...

Page 179: ...01 6 undefined 1113 01 ENGINE ASSEMBLY LH Side View RH Side View ...

Page 180: ...01 7 ENGINE ASSEMBLY undefined 1113 01 3 G23D ENGINE STRUCTURE Front View Side View ...

Page 187: ...01 14 undefined 1113 01 ENGINE ASSEMBLY 5 GENERAL DIAGNOSIS ...

Page 188: ...01 15 ENGINE ASSEMBLY undefined 1113 01 General Diagnosis Cont d ...

Page 189: ...01 16 undefined 1113 01 ENGINE ASSEMBLY General Diagnosis Cont d ...

Page 190: ...01 17 ENGINE ASSEMBLY undefined 1113 01 General Diagnosis Cont d ...

Page 191: ...01 18 undefined 1113 01 ENGINE ASSEMBLY General Diagnosis Cont d ...

Page 193: ...01 20 undefined 1113 01 ENGINE ASSEMBLY 2 Fastener Tightening Specifications ...

Page 194: ...01 21 ENGINE ASSEMBLY undefined 1113 01 Fastener Tightening Specifications Cont d ...

Page 195: ...01 22 undefined 1113 01 ENGINE ASSEMBLY 2 Performance Curve ...

Page 196: ......

Page 203: ...04 4 undefined 2112 01 ENGINE COOLING SYSTEM 2 FASTENER TIGHTENING SPECIFICATIONS ...

Page 212: ...05 4 undefined 1452 01 ENGINE ELECTRICAL SYSTEM 2 Ignition System Cont d ...

Page 221: ...06 5 CRUISE CONTROL SYSTEM undefined 8510 23 2 CIRCUIT DIAGRAM 1 Configuration ...

Page 229: ...06 5 CRUISE CONTROL SYSTEM undefined 8510 23 2 CIRCUIT DIAGRAM 1 Configuration ...

Page 239: ...0 7 FUSE AND RELAY undefined 8210 01 2 Interior Fuse and Relay Box On the Passenger Side ...

Page 246: ...02 5 STICS undefined 8710 01 Rated Load ...

Page 247: ...02 6 undefined 8710 01 STICS Input Signals ...

Page 293: ...02 52 undefined 8710 01 STICS 2 STICS Output Signals and Others ...

Page 301: ......

Page 304: ......

Page 309: ...03 10 undefined 7010 06 IMMO 5 CIRCUIT DIAGRAM ...

Page 312: ...05 4 undefined 8010 01 CLUSTER 2 WARNING INDICATOR PANEL ...

Page 313: ...05 5 CLUSTER undefined 8010 01 ...

Page 324: ...05 16 undefined 8010 01 CLUSTER 4 CIRCUIT DIAGRAM ...

Page 325: ...05 17 CLUSTER undefined 8010 01 ...

Page 336: ...08 6 undefined 7810 01 WIPER 2 SYSTEM LAYOUT OF WIPER AND WASHER WITH RAIN SENSOR ...

Page 337: ...08 7 WIPER undefined 7810 01 ...

Page 342: ...08 12 undefined 7810 01 WIPER 4 WIPER AND WASHER SYSTEM RELATED CIRCUIT DIAGRAM ...

Page 360: ...10 10 undefined 8790 03 PAS 4 CIRCUIT DIAGRAM ...

Page 362: ...02 3 ION 4 SPEED ACTYON 2010 01 3410 01 3640 01 ION 4 SPEED GENERAL 1 SPECIFICATIONS ...

Page 363: ...02 4 ACTYON 2010 01 3410 01 ION 4 SPEED 2 FASTENER TIGHTENING SPECIFICATIONS ...

Page 372: ...02 13 ION 4 SPEED ACTYON 2010 01 3410 01 ...

Page 376: ...02 17 ION 4 SPEED ACTYON 2010 01 3410 01 Solenoid Operation during Gearshifts ...

Page 380: ...02 21 ION 4 SPEED ACTYON 2010 01 3410 01 1 Hydraulic Control Circuit ...

Page 390: ...02 31 ION 4 SPEED ACTYON 2010 01 3410 01 ...

Page 395: ...02 36 ACTYON 2010 01 3410 01 ION 4 SPEED 1 Park and Neutral ...

Page 397: ...02 38 ACTYON 2010 01 3410 01 ION 4 SPEED 2 Reverse ...

Page 399: ...02 40 ACTYON 2010 01 3410 01 ION 4 SPEED 3 Manual 1 ...

Page 401: ...02 42 ACTYON 2010 01 3410 01 ION 4 SPEED 4 Drive 1 ...

Page 403: ...02 44 ACTYON 2010 01 3410 01 ION 4 SPEED 5 Drive 2 and Manual 2 ...

Page 405: ...02 46 ACTYON 2010 01 3410 01 ION 4 SPEED 6 Drive 3 and Manual 3 ...

Page 408: ...02 49 ION 4 SPEED ACTYON 2010 01 3410 01 7 Drive 3 Lock Up and Manual 3 Lock Up ...

Page 410: ...02 51 ION 4 SPEED ACTYON 2010 01 3410 01 8 Drive 4 Overdrive ...

Page 413: ...02 54 ACTYON 2010 01 3410 01 ION 4 SPEED 9 Drive 4 Lock Up ...

Page 419: ...0 6 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T 3 Internal Assembly Figure 2WD 4WD ...

Page 420: ...0 7 DSI M78 6 SPEED A T ACTYON 2010 01 3650 01 4 Shift Pattern ...

Page 421: ...0 8 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T 3 TIGHTENING TORQUE ...

Page 434: ...0 21 DSI M78 6 SPEED A T ACTYON 2010 01 3650 01 Overall Hydraulic Circui ...

Page 437: ...0 24 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T Manual 1st C2 B2 ON 3 536 ...

Page 439: ...0 26 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T Auto 1st C2 OWC ON 3 536 ...

Page 441: ...0 28 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T Auto 2nd C2 B1 ON 2 143 ...

Page 443: ...0 30 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T 2nd Lockup C2 B1 TCC ON ...

Page 445: ...0 32 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T 3rd Gear C2 C3 ON 1 478 ...

Page 447: ...0 34 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T 4th 4th LHM C1 C2 ON 1 156 ...

Page 449: ...0 36 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T 5th Gear C1 C3 ON 0 866 ...

Page 451: ...0 38 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T 6th Gear C1 B1 ON 0 677 ...

Page 453: ...0 40 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T Reverse C3 B2 ON 3 094 ...

Page 455: ...0 42 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T Reverse at LHM C3 B2 ON ...

Page 457: ...0 44 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T Park ...

Page 459: ...0 46 ACTYON 2010 01 3650 01 DSI M78 6 SPEED A T Neutral ...

Page 460: ...0 95 DSI M78 6 SPEED A T ACTYON 2010 01 3110 01 1 WIRING DIAGRAM DIAGNOSIS AND TESTING ...

Page 462: ...0 97 DSI M78 6 SPEED A T ACTYON 2010 01 3110 01 Connector J2 B Connector J3 C ...

Page 464: ...0 99 DSI M78 6 SPEED A T ACTYON 2010 01 3110 01 3 Inhibitor Switch Connector J5 ...

Page 466: ...0 101 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 ...

Page 468: ...0 103 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 Schematic Connector Details ...

Page 469: ...0 104 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Details DTC Clearing ...

Page 472: ...0 107 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Clearing ...

Page 475: ...0 110 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T Resistance Values ...

Page 476: ...0 111 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Details DTC Clearing ...

Page 478: ...0 113 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 Schematic Connector Details ...

Page 479: ...0 114 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Details ...

Page 480: ...0 115 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Clearing ...

Page 483: ...0 118 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Clearing ...

Page 485: ...0 120 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Details DTC Details ...

Page 487: ...0 122 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Details ...

Page 488: ...0 123 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Clearing ...

Page 490: ...0 125 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Details DTC Clearing ...

Page 493: ...0 128 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Clearing ...

Page 495: ...0 130 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Description Schematic Connector Details ...

Page 496: ...0 131 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Details ...

Page 497: ...0 132 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T ...

Page 498: ...0 133 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 ...

Page 499: ...0 134 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Clearing ...

Page 501: ...0 136 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T Schematic Connector Details ...

Page 502: ...0 137 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Details ...

Page 503: ...0 138 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T ...

Page 504: ...0 139 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 DTC Clearing ...

Page 506: ...0 141 DSI M78 6 SPEED A T ACTYON 2010 01 3110 00 Schematic Connector Details DTC Details ...

Page 507: ...0 142 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Clearing ...

Page 509: ...0 144 ACTYON 2010 01 3110 00 DSI M78 6 SPEED A T DTC Details DTC Clearing ...

Page 522: ...0 8 ACTYON 2010 01 3722 01 TGS LEVER 2 Electric Circuit ...

Page 524: ...0 10 ACTYON 2010 01 3722 01 TGS LEVER 3 Shift Lock Solenoid Function ...

Page 529: ...03 5 M T ACTYON 2010 01 3170 01 2 Tightening Torque ...

Page 533: ......

Page 545: ...0 6 ACTYON 2010 01 3240 01 TRANSFER CASE 2 SYSTEM LAYOUT AND OPERATION 1 System Layout ...

Page 549: ...0 10 ACTYON 2010 01 3240 01 TRANSFER CASE 2 Flow Layout ...

Page 550: ...0 11 TRANSFER CASE ACTYON 2010 01 3240 01 3 2H Mode Rear Wheel Drive 1 Layout ...

Page 551: ...0 12 ACTYON 2010 01 3240 01 TRANSFER CASE 4 4H Mode 4 Wheel Drive High speed 1 Layout ...

Page 552: ...0 13 TRANSFER CASE ACTYON 2010 01 3240 01 4 4L Mode 4 Wheel Drive Low speed 1 Layout ...

Page 555: ...08 4 ACTYON 2010 01 4892 01 ESP 2 SECTIONAL DRAWING 1 Front Disc Brake 2 Rear Disc Brake ...

Page 582: ...08 31 ESP ACTYON 2010 01 4892 01 8 HYDRAULIC CIRCUIT DIAGRAM OF ESP SYSTEM ...

Page 588: ...08 37 ESP ACTYON 2010 01 4892 01 1 Input and Output Diagram Of ABS System ...

Page 593: ...09 4 ACTYON 2010 01 4610 01 POWER STEERING OVERVIEW AND OPERATION 1 SYSTEM LAYOUT ...

Page 594: ...09 5 POWER STEERING ACTYON 2010 01 4610 01 ...

Page 595: ...09 6 ACTYON 2010 01 4610 01 POWER STEERING 2 COMPONENTS ...

Page 596: ...09 7 POWER STEERING ACTYON 2010 01 4610 01 ...

Page 601: ...02 7 AIR BAG ACTYON 2010 01 8810 03 ...

Page 605: ...02 11 AIR BAG ACTYON 2010 01 8810 03 1 Components ...

Page 613: ...02 19 AIR BAG ACTYON 2010 01 8810 03 10 Electrical Wiring Diagram ...

Page 622: ...04 6 ACTYON 2010 01 7340 01 SUNROOF 6 Circuit Diagram of Sunroof ...

Page 627: ...07 3 BODY REPAIR ACTYON 2010 01 4110 01 4110 01 BODY REPAIR GENERAL 1 DIMENSIONS ...

Page 628: ...07 4 ACTYON 2010 01 4110 01 BODY REPAIR 2 JACK UP POINTS ...

Page 633: ......

Page 639: ...01 7 AIR CONDITIONER ACTYON 2010 01 6810 20 2 Components ...

Page 642: ......

Page 643: ...ECU GASOLINE 0000 00 ECU GASOLINE 1 ECU GASOLINE 3 ...

Page 644: ......

Page 645: ...0 3 ECU GASOLINE ACTYON 2010 01 0000 00 0000 00 ECU GASOLINE 1 ECU GASOLINE ...

Page 646: ...0 4 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 647: ...0 5 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 648: ...0 6 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 649: ...0 7 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 650: ...0 8 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 651: ...0 9 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 652: ...0 10 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 653: ...0 11 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 654: ...0 12 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 655: ...0 13 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 656: ...0 14 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 657: ...0 15 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 658: ...0 16 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 659: ...0 17 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 660: ...0 18 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 661: ...0 19 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 662: ...0 20 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 663: ...0 21 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 664: ...0 22 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 665: ...0 23 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 666: ...0 24 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 667: ...0 25 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 668: ...0 26 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 669: ...0 27 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 670: ...0 28 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 671: ...0 29 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 672: ...0 30 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 673: ...0 31 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 674: ...0 32 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 675: ...0 33 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 676: ...0 34 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 677: ...0 35 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 678: ...0 36 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 679: ...0 37 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 680: ...0 38 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 681: ...0 39 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 682: ...0 40 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 683: ...0 41 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 684: ...0 42 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 685: ...0 43 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 686: ...0 44 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 687: ...0 45 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 688: ...0 46 ACTYON 2010 01 0000 00 ECU GASOLINE ...

Page 689: ...0 47 ECU GASOLINE ACTYON 2010 01 0000 00 ...

Page 690: ......

Page 691: ...ECU DIESEL 0000 00 ECU DIESEL DIAGNOSIS 1 ECU DIESEL 3 ...

Page 692: ......

Page 693: ...0 3 ECU DIESEL ACTYON 2010 01 0000 00 0000 00 ECU DIESEL 1 ECU DIESEL ...

Page 694: ...0 4 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 695: ...0 5 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 696: ...0 6 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 697: ...0 7 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 698: ...0 8 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 699: ...0 9 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 700: ...0 10 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 701: ...0 11 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 702: ...0 12 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 703: ...0 13 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 704: ...0 14 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 705: ...0 15 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 706: ...0 16 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 707: ...0 17 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 708: ...0 18 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 709: ...0 19 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 710: ...0 20 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 711: ...0 21 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 712: ...0 22 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 713: ...0 23 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 714: ...0 24 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 715: ...0 25 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 716: ...0 26 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 717: ...0 27 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 718: ...0 28 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 719: ...0 29 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 720: ...0 30 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 721: ...0 31 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 722: ...0 32 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 723: ...0 33 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 724: ...0 34 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 725: ...0 35 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 726: ...0 36 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 727: ...0 37 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 728: ...0 38 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 729: ...0 39 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 730: ...0 40 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 731: ...0 41 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 732: ...0 42 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 733: ...0 43 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 734: ...0 44 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 735: ...0 45 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 736: ...0 46 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 737: ...0 47 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 738: ...0 48 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 739: ...0 49 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 740: ...0 50 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 741: ...0 51 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 742: ...0 52 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 743: ...0 53 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 744: ...0 54 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 745: ...0 55 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 746: ...0 56 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 747: ...0 57 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 748: ...0 58 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 749: ...0 59 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 750: ...0 60 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 751: ...0 61 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 752: ...0 62 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 753: ...0 63 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 754: ...0 64 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 755: ...0 65 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 756: ...0 66 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 757: ...0 67 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 758: ...0 68 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 759: ...0 69 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 760: ...0 70 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 761: ...0 71 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 762: ...0 72 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 763: ...0 73 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 764: ...0 74 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 765: ...0 75 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 766: ...0 76 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 767: ...0 77 ECU DIESEL ACTYON 2010 01 0000 00 ...

Page 768: ...0 78 ACTYON 2010 01 0000 00 ECU DIESEL ...

Page 769: ...BRAKE 0000 00 BRAKE DIAGNOSIS 1 BRAKE 3 ...

Page 770: ......

Page 771: ...0 3 BRAKE ACTYON 2010 01 0000 00 0000 00 BRAKE 1 BRAKE ...

Page 772: ...0 4 ACTYON 2010 01 0000 00 BRAKE ...

Page 773: ...0 5 BRAKE ACTYON 2010 01 0000 00 ...

Page 774: ...0 6 ACTYON 2010 01 0000 00 BRAKE ...

Page 775: ...0 7 BRAKE ACTYON 2010 01 0000 00 ...

Page 776: ...0 8 ACTYON 2010 01 0000 00 BRAKE ...

Page 777: ...0 9 BRAKE ACTYON 2010 01 0000 00 ...

Page 778: ...0 10 ACTYON 2010 01 0000 00 BRAKE ...

Page 779: ...0 11 BRAKE ACTYON 2010 01 0000 00 ...

Page 780: ...0 12 ACTYON 2010 01 0000 00 BRAKE ...

Page 781: ...AIR BAG 0000 00 AIR BAG DIAGNOSIS 1 AIR BAG 3 ...

Page 782: ......

Page 783: ...0 3 AIR BAG ACTYON 2010 01 0000 00 0000 00 AIR BAG 1 AIR BAG ...

Page 784: ...0 4 ACTYON 2010 01 0000 00 AIR BAG ...

Page 785: ...0 5 AIR BAG ACTYON 2010 01 0000 00 ...

Page 786: ...0 6 ACTYON 2010 01 0000 00 AIR BAG ...

Page 787: ...0 7 AIR BAG ACTYON 2010 01 0000 00 ...

Page 788: ...0 8 ACTYON 2010 01 0000 00 AIR BAG ...

Page 789: ...0 9 AIR BAG ACTYON 2010 01 0000 00 ...

Page 790: ...0 10 ACTYON 2010 01 0000 00 AIR BAG ...

Page 791: ...CCCS 0000 00 CCCS DIAGNOSIS 1 CCCS 3 ...

Page 792: ......

Page 793: ...0 3 CCCS ACTYON 2010 01 0000 00 0000 00 CCCS 1 CCCS ...

Page 794: ...0 4 ACTYON 2010 01 0000 00 CCCS ...

Page 795: ...0 5 CCCS ACTYON 2010 01 0000 00 ...

Page 796: ...0 6 ACTYON 2010 01 0000 00 CCCS ...

Page 797: ...0 7 CCCS ACTYON 2010 01 0000 00 ...

Page 798: ...0 8 ACTYON 2010 01 0000 00 CCCS ...

Page 799: ...0 9 CCCS ACTYON 2010 01 0000 00 ...

Page 800: ...0 10 ACTYON 2010 01 0000 00 CCCS ...

Page 801: ...0 11 CCCS ACTYON 2010 01 0000 00 ...

Page 802: ...0 12 ACTYON 2010 01 0000 00 CCCS ...

Page 803: ...0 13 CCCS ACTYON 2010 01 0000 00 ...

Page 804: ...0 14 ACTYON 2010 01 0000 00 CCCS ...

Page 805: ...0 15 CCCS ACTYON 2010 01 0000 00 ...

Page 806: ...0 16 ACTYON 2010 01 0000 00 CCCS ...

Page 807: ...0 17 CCCS ACTYON 2010 01 0000 00 ...

Page 808: ...0 18 ACTYON 2010 01 0000 00 CCCS ...

Page 809: ...0 19 CCCS ACTYON 2010 01 0000 00 ...

Page 810: ...0 20 ACTYON 2010 01 0000 00 CCCS ...

Page 811: ...0 21 CCCS ACTYON 2010 01 0000 00 ...

Page 812: ...0 22 ACTYON 2010 01 0000 00 CCCS ...

Page 813: ...0 23 CCCS ACTYON 2010 01 0000 00 ...

Page 814: ...0 24 ACTYON 2010 01 0000 00 CCCS ...

Page 815: ...0 25 CCCS ACTYON 2010 01 0000 00 ...

Page 816: ...0 26 ACTYON 2010 01 0000 00 CCCS ...

Page 817: ...0 27 CCCS ACTYON 2010 01 0000 00 ...

Page 818: ......

Page 819: ...FATC 0000 00 FATC DIAGNOSIS 1 SELF DIAGNOSIS 3 ...

Page 820: ......

Page 825: ...FFH 0000 00 FFH DIAGNOSIS 1 FFH 3 ...

Page 826: ......

Page 827: ...0 3 FFH ACTYON 2010 01 0000 00 0000 00 FFH 1 FFH ...

Page 828: ...0 4 ACTYON 2010 01 0000 00 FFH ...

Page 829: ...0 5 FFH ACTYON 2010 01 0000 00 ...

Page 830: ...0 6 ACTYON 2010 01 0000 00 FFH ...

Page 831: ...P TRUNK 0000 00 P TRUNK DIAGNOSIS 1 P TRUNK 3 ...

Page 832: ......

Page 833: ...0 3 P TRUNK ACTYON 2010 01 0000 00 0000 00 P TRUNK 1 P TRUNK ...

Page 834: ...0 4 ACTYON 2010 01 0000 00 P TRUNK ...

Page 835: ...RAIN SENSOR 0000 00 RAIN SENSOR DIAGNOSIS 1 TROUBLE SHOOTING 3 ...

Page 836: ......

Page 839: ...STICS 0000 00 STICS DIAGNOSIS 1 STICS 3 ...

Page 840: ......

Page 841: ...0 3 STICS ACTYON 2010 01 0000 00 0000 00 STICS 1 STICS ...

Page 842: ...0 4 ACTYON 2010 01 0000 00 STICS ...

Page 843: ...TC 0000 00 TC DIAGNOSIS 1 TC 3 ...

Page 844: ......

Page 845: ...0 3 TC ACTYON 2010 01 0000 00 0000 00 TC 1 TC ...

Page 846: ...0 4 ACTYON 2010 01 0000 00 TC ...

Page 847: ...0 5 TC ACTYON 2010 01 0000 00 ...

Page 848: ...0 6 ACTYON 2010 01 0000 00 TC ...

Page 849: ...TCU 0000 00 TCU DIAGNOSIS 1 TCU 3 ...

Page 850: ......

Page 851: ...0 3 TCU ACTYON 2010 01 0000 00 0000 00 TCU 1 TCU ...

Page 852: ...0 4 ACTYON 2010 01 0000 00 TCU ...

Page 853: ...0 5 TCU ACTYON 2010 01 0000 00 ...

Page 854: ...0 6 ACTYON 2010 01 0000 00 TCU ...

Page 855: ...0 7 TCU ACTYON 2010 01 0000 00 ...

Page 856: ...0 8 ACTYON 2010 01 0000 00 TCU ...

Page 857: ...0 9 TCU ACTYON 2010 01 0000 00 ...

Page 858: ...0 10 ACTYON 2010 01 0000 00 TCU ...

Page 859: ...0 11 TCU ACTYON 2010 01 0000 00 ...

Page 860: ...0 12 ACTYON 2010 01 0000 00 TCU ...

Page 861: ...0 13 TCU ACTYON 2010 01 0000 00 ...

Page 862: ...0 14 ACTYON 2010 01 0000 00 TCU ...

Page 863: ...0 15 TCU ACTYON 2010 01 0000 00 ...

Page 864: ...0 16 ACTYON 2010 01 0000 00 TCU ...

Page 865: ...0 17 TCU ACTYON 2010 01 0000 00 ...

Page 866: ...0 18 ACTYON 2010 01 0000 00 TCU ...

Page 867: ...0 19 TCU ACTYON 2010 01 0000 00 ...

Page 868: ......

Page 869: ...TGS LEVER 0000 00 TGS LEVER DIAGNOSIS 1 TGS LEVER 3 ...

Page 870: ......

Page 871: ...0 3 TGS LEVER ACTYON 2010 01 0000 00 0000 00 TGS LEVER 1 TGS LEVER ...

Page 872: ...0 4 ACTYON 2010 01 0000 00 TGS LEVER ...