Page 4

SYSTEM OVERVIEW

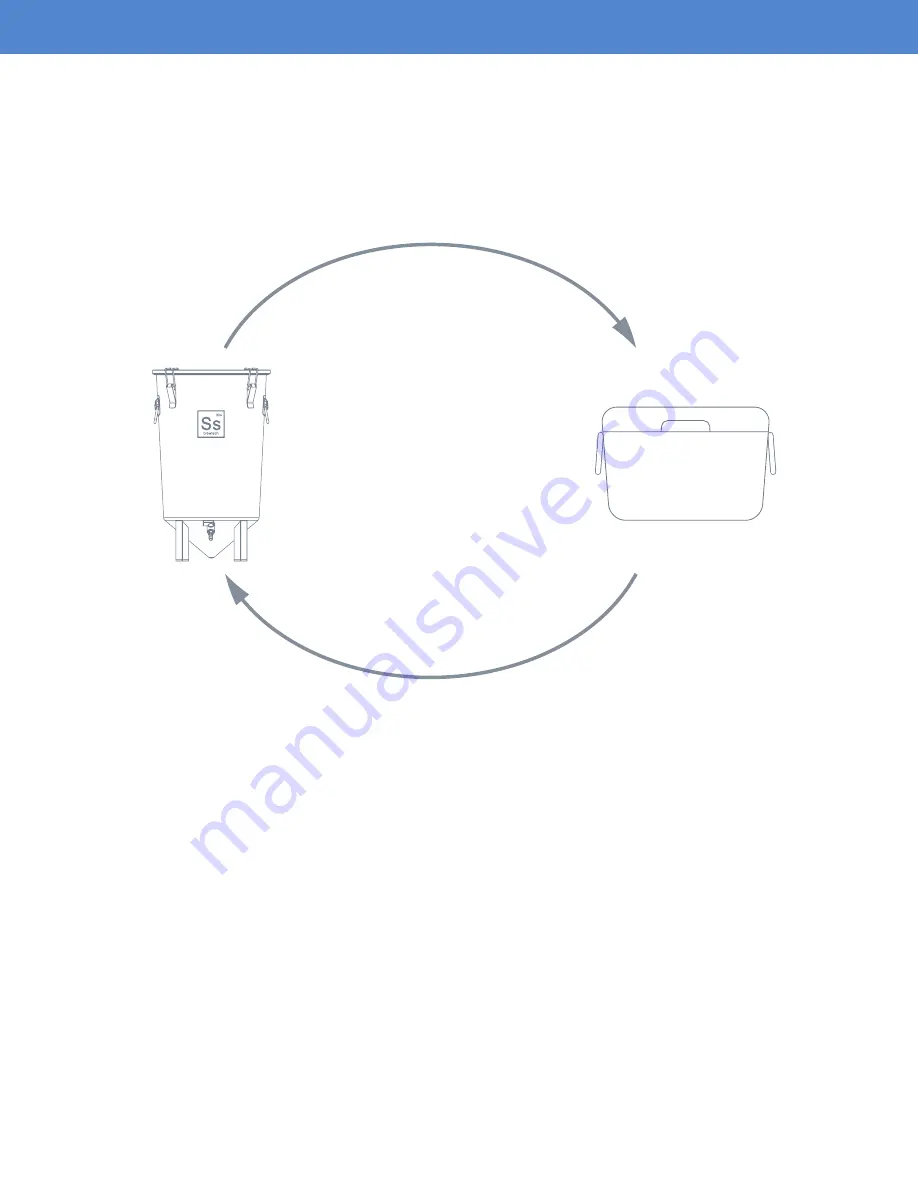

The basic principle of the Fermentation Temperature Stabilization System (FTSs

2

) is to pump chilled

water or glycol through the immersion coil when the temperature of your wort is greater than the controller

set-point. The system is designed to use chilled ice water from a common cooler or glycol chiller. In this

configuration, the submersible pump will be placed in the bottom of the cooler.

The FTSs

2

is intended to be a low pressure closed loop system. Water or glycol pumped from the cooler

to the fermenter is then returned to the cooler to be used again.

If your setup requires more distance from the fermenter to the cooler, you can purchase common vinyl

tubing at most hardware stores. The pump is capable lifting the water up to 10 feet. Pumping beyond

10 feet will negatively affect efficiency.

In a heating mode, the controller will activate the low wattage heater, which will in-turn begin to slowly

raise the temperature of the liquid volume starting at the fermenter’s cone. From there, convection will

foster the newly introduced heat to radiate up to the remaining liquid volume not in direct contact with

the cone. This key characteristic insures that hot-spots don’t form within the fermenter.

INTRODUCTION

Warm Water or Glycol

Cold Water or Glycol

Low Pressure

Closed Loop System