8

field repair

GENERAL

Geareducers can be repaired in the field—however, major repairs

require the use of a fully equipped machine shop. When field repair

or replacement of parts is necessary, the following procedure is

recommended for the disassembly and assembly of the unit. If any

O-ring, oil seal or gasket is to be reused, care should be taken

not to damage it during disassembly. Parts which contain O-rings

or seals should not be jerked or twisted past a shoulder or edge.

These parts are marked with an asterisk (*) in the description

below. O-rings, oil seal and gaskets should be carefully inspected

for damage before being reinstalled. Marley recommends that new

O-rings and oil seal be installed during a major overhaul.

DISASSEMBLY

Part numbers and references—refer to

Figure 3

.

1. Drain oil.

2. Remove outer ring of bolts in pinion cage and remove pinion

subassembly*.

Note

—The thickness of the shim pack (

320

) is important in reset-

ting the gears. The shim pack should either be saved or carefully

measured with a micrometer. If the gears are to be replaced,

record the pinion setting distance that is etched on the pinion

gear. See

Figure 4

.

3. Remove water slinger*.

4. Remove bearing retainer and shim pack (

420

) from top of

case.

Note

—The thickness of this shim pack is important in

the endplay and backlash setting of the gears. The shim

pack should either be saved or carefully measured with a

micrometer.

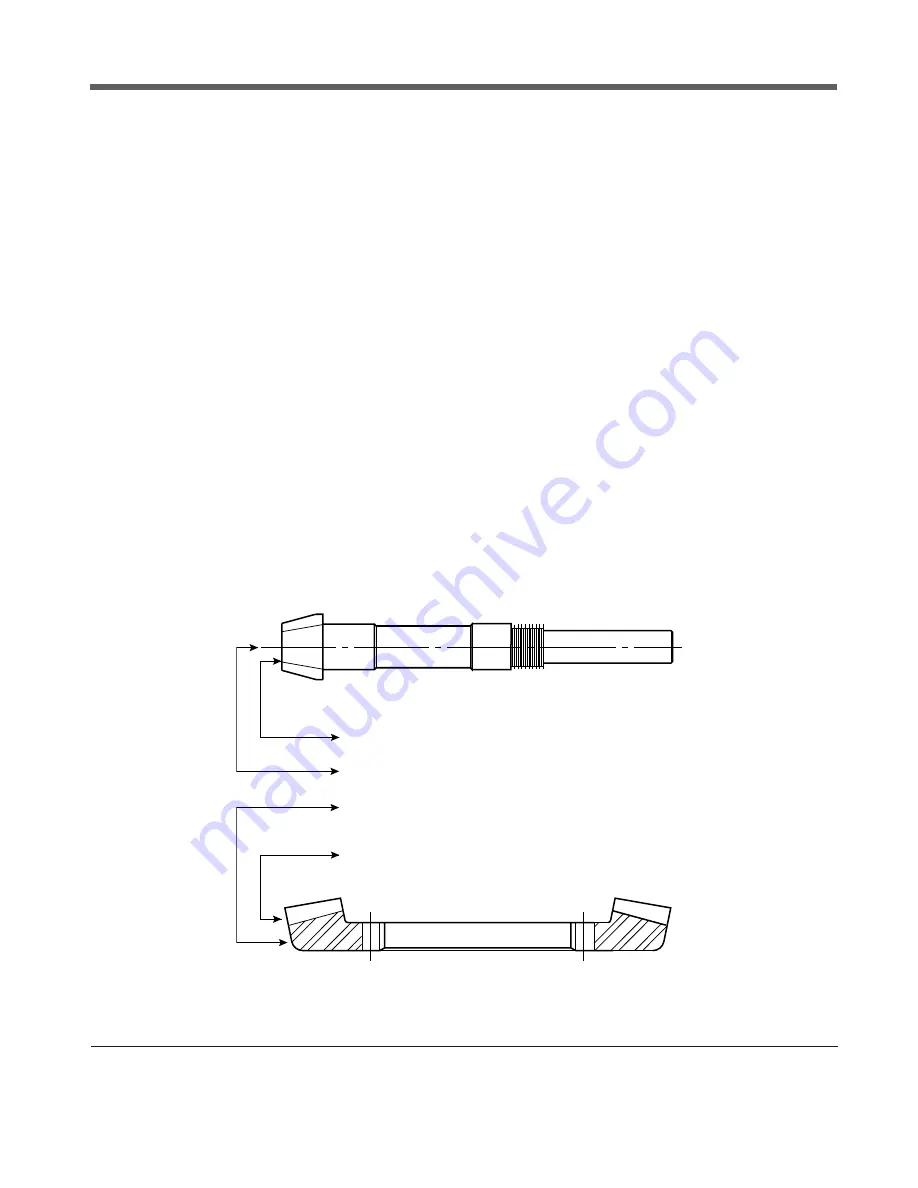

FIGURE 4

Gear Match Numbers and Setting Data

MATCHED NUMBER TO BE COMPARED WITH THE SAME

NUMBER ON THE RING GEAR. (EXAMPLE CO-43)

PINION SETTING DISTANCE. (EXAMPLE 4.860)

BACKLASH (NORMAL) AT WHICH THE GEARS WERE

LAPPED. (EXAMPLE .010)

MATCHED NUMBER TO BE COMPARED WITH THE SAME

NUMBER ON THE PINION GEAR. (EXAMPLE C0-43)

THE PINION SETTING DISTANCE IS THE DISTANCE

THE END OF THE PINION SHOULD BE FROM THE

CENTERLINE OF THE RING GEAR SHAFT.