32

Disassembly and assembly

CRL/EN (1810) 2.2

7.7

Replacing the impeller and the wear ring

If the play has risen to 0,9 mm or greater due to wear then both wear rings are replaced.

7.7.1

Disassembling the impeller

1 Remove the Top Pull Out unit, see paragraph 7.5.1 "Disassembling the Top Pull Out

unit OH3" or paragraph 7.6.1 "Disassembly Top Pull Out unit OH5".

2 Unlock the set screw (1825) and remove the cap nut (1820).

3 Remove the impeller (0120) with a pulley puller, or wrest the impeller by inserting for

instance 2 big screwdrivers between the impeller and the pump cover (0110).

4 Remove the impeller key (1860).

7.7.2

Mounting the impeller

1 Place the impeller key (1860) in the key way of the pump shaft.

2 Push the impeller onto the pump shaft.

3 Fit the cap nut. For tightening moment of the nut see paragraph 10.1.2 "Tightening

4 Fit the set screw (1825).

7.7.3

Disassembling the wear rings

After removing the Top Pull Out unit (see paragraph 7.5.1 "Disassembling the Top Pull

Out unit OH3" or paragraph 7.6.1 "Disassembly Top Pull Out unit OH5") the wear rings

can be removed. In most cases the ring has been fixed so tightly that it cannot be

removed undamaged.

1 Disassembling the impeller, see paragraph 7.7.1 "Disassembling the impeller"

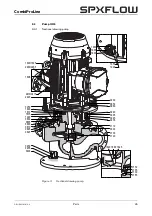

Figure 5:

Removal of wear ring.

b

d

A

B

C

D

b

d

Summary of Contents for Johnson Pump CombiProLine OH3

Page 2: ......

Page 4: ...2 EC EN 1712 6 0 ...

Page 6: ...4 INT EN 1512 1 2 ...

Page 10: ...8 CRL EN 1810 2 2 ...

Page 20: ...18 General CRL EN 1810 2 2 ...

Page 40: ...38 Dimensions CRL EN 1810 2 2 ...

Page 52: ...50 Parts CRL EN 1810 2 2 ...

Page 66: ...64 ORDFORM 1512 3 3 EN ...