3

MINI INSTRUCTIONS

For complete instructions on installation, operation, and maintenance, consult manual.

I . INSTALLATION

1. Install on level surface.

2. Ambient temperature range: 35 to 120

°

F (1.7 to 49

°

C) [ if low ambient package supplied: -10 to 120

°

F (-23 to 49

°

C) ]

3. Install purge mufflers if shipped separately.

4. Connect air from compressor to inlet.

• Maximum compressed air temperature: 120

°

F (49

°

C)

• Maximum compressed air pressure: Refer to serial number tag.

• Minimum compressed air pressure: See section 2.2.1.2 .

5. Connect outlet to air system.

6. Refer to serial number tag for correct voltage. Make electrical connection to terminal strip in electrical enclosure. Standard units: connect

line to position 5, neutral to position 6 and ground to position 7.

Automatic purge saving system: connect wires to positions 2 and 3; ground to position 1.

7. Set controller for 120V or 240V using selector switch.

I I. START UP

1. Set or verify controller settings. See section 3.1.1.

2. SLOWLY pressurize unit.

3. Energize dryer by turning on/off switch on. ("I" is on; "O" is off)

4. Adjust purge air flow rate. Turn purge rate valve until Purge Pressure Gauge reads as shown in the following table.

NOTE: One tower must be purging when setting purge pressure.

III . OPERATIONAL CHECKPOINTS

1. Check that dryer is energized (indicating lights are illuminated)

2. MOISTURE INDICATOR - Indicator should be green (Allow 4 hours after start up for indicator to turn green).

3. TOWER PRESSURE GAUGES -

• Tower on line should read line pressure

• Tower off line should read 2 psig or less while purging. If pressure exceeds 2 psig replace purge muffler elements.

NOTE: An extra set of elements is shipped with dryer.

4. PURGE PRESSURE GAUGE - Verify proper setting.

5. CHECK FOR ALARM CONDITION.

IV . DEPRESSURIZATION

Isolate dryer. Run timer until both tower pressure gauges read 0 psig.

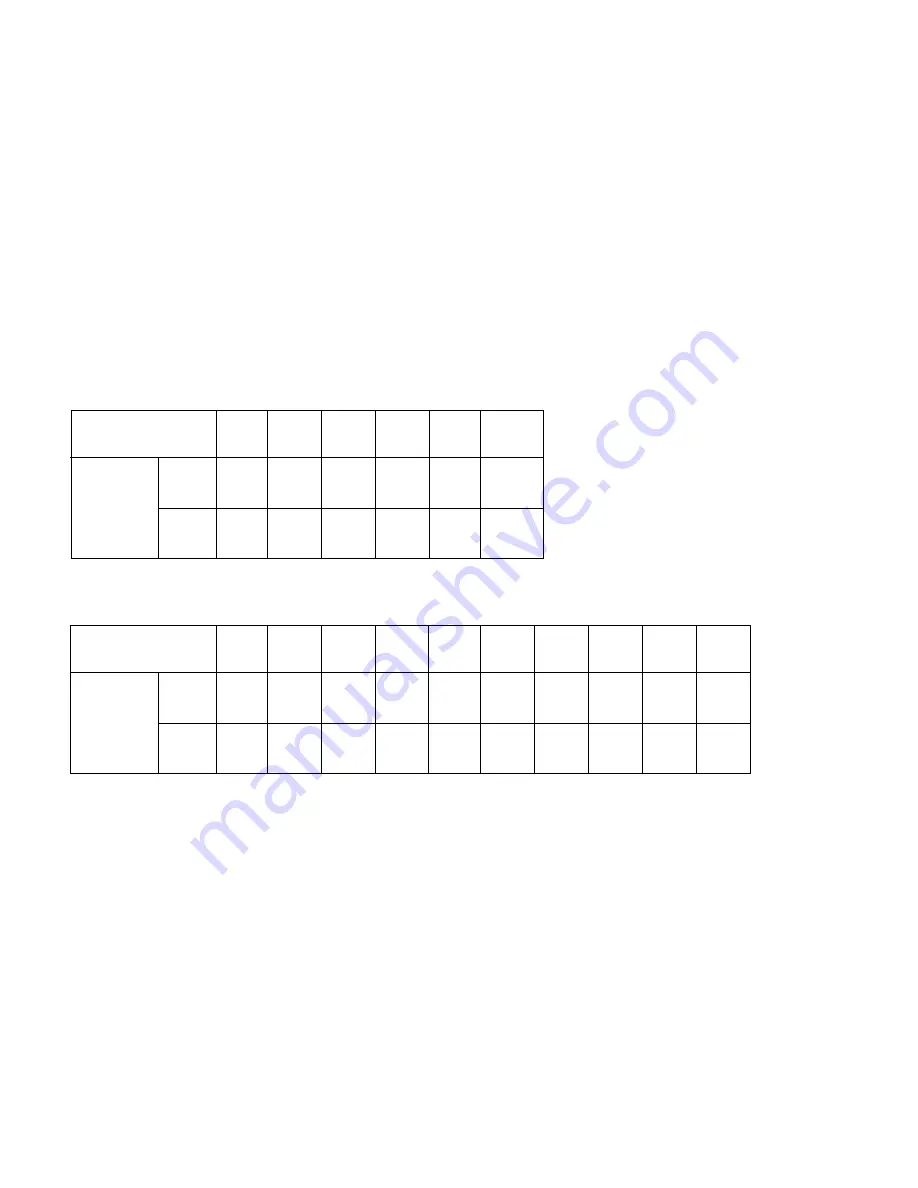

150 psig M.W.P. models

4

Min.

10

Min.

250 psig M.W.P. models

CYCLE

TIME

SETTING

80

79

78

77

76

75

70

64

60

57

4

Min.

10

Min.

—

—

—

—

—

132

123

115

108

102

INLET PRESSURE

60-100

110

120

130

140

150

(psig)

CYCLE

TIME

SETTING

45

43

41

39

37

36

70

66

63

60

58

56

INLET PRESSURE

125

130

135

140

145

150

175

200

225

250

(psig)