15

150 psig MWP

100%

234 sec.

90%

211 sec.

80%

187 sec.

70%

164 sec.

60%

140 sec.

50%

117 sec.

40%

94 sec.

30%

70 sec.

250 psig MWP

100%

174 sec.

90%

157 sec.

80%

139 sec.

70%

122 sec.

60%

104 sec.

50%

87 sec.

40%

70 sec.

30%

52 sec.

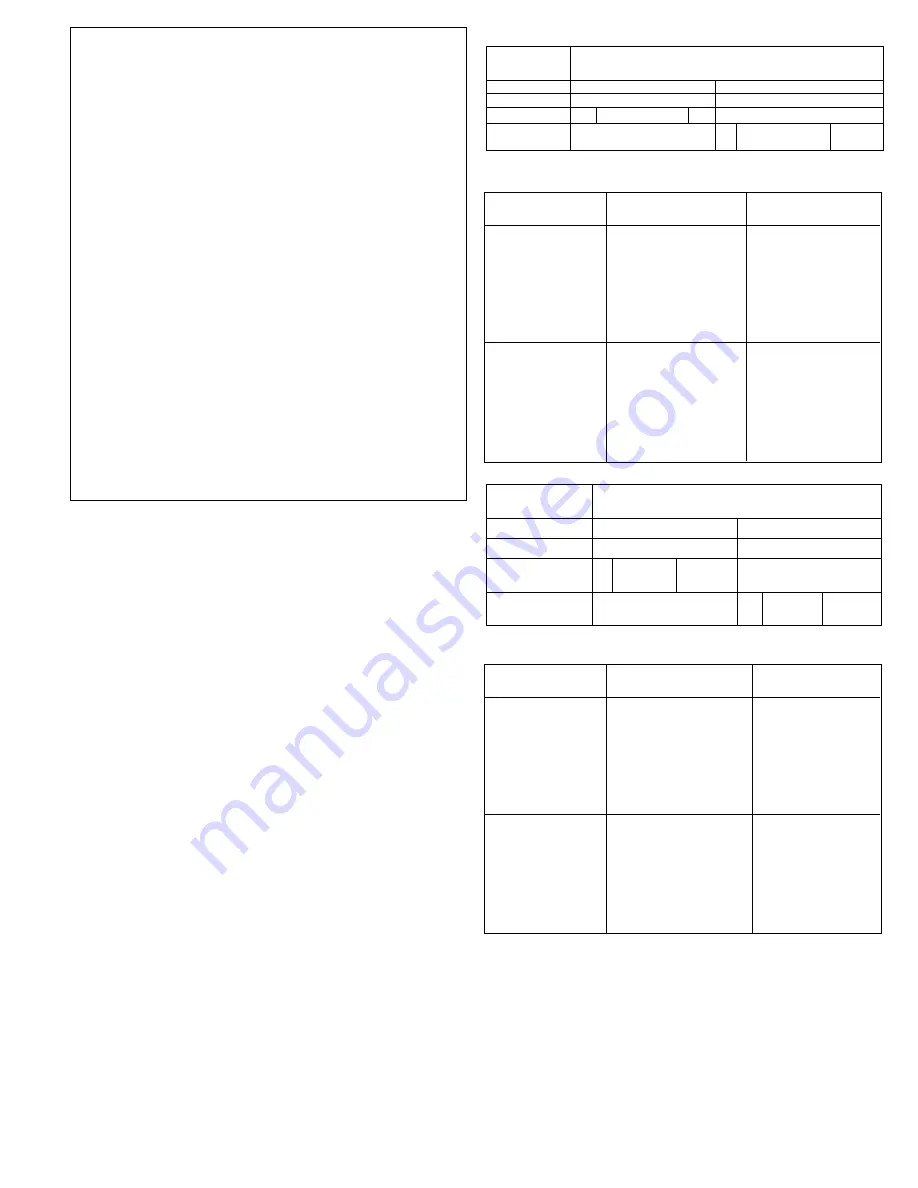

9B Cl OPEN CLOSED CLOSED

6" (

2

)

ECONOMIZER SWITCH

PURGE TIME

SETTING

TIME (Min.)

0 1 2 3 4 5 6 7 8 9 10

3A OPEN CLOSED

3B CLOSED OPEN

9B Cl 6" OPEN (1) Cl CLOSED

9A CLOSED Cl OPEN CLOSED

6" (1)

3.2.2.5 Tower status lights - indicate when left and right

towers are drying and regenerating.

3.2.2.6 Valve energized lights

Four LEDs are furnished on controller to indicate which air

control valves are energized at any particular time

3.2.2.7 Average Demand Meter

The demand meter displays the average demand on the

dryer for the last 4 cycles. It is determined by dividing 40 (time

to complete 4 cycles at full flow) by the actual time to complete

the last 4 cycles.

3.2.2.8 Tower pressure gauges

3.2.2.8.1 Periodically check tower pressure gauges to

verify that tower pressure gauge of tower on-line reads line

pressure and tower pressure gauge of tower off-line reads

below 2 psig.

NOTE

Read off-line tower gauge when tower is purging (air

exhausting from muffler)

3.2.2.8.2 Check mufflers for back pressure

Excessive back pressure may result due to the accumu-

lation of dust in the muffler. This sometimes occurs after start-

up because of dusting of the desiccant during tower filling and

dryer transport.

If the tower pressure gauge of the off-stream tower rises

out of the black area on the gauge dial, muffler elements

should be replaced. A set of purge exhaust muffler replace-

ment elements is supplied with the dryer.

3.2.3 All MODELS - Determine if air control valves are

operating and sequencing correctly.

Refer to Section 1.2 and Figure 1A and 1B for a general

description of operating sequence.

3.2.3.1 Inlet switching and purge/repressurization valves.

1) Tower pressure gauge of tower on-line should read line

pressure. No air should be leaking from purge/repressurization

valve of the on-line tower.

2) Tower pressure gauge of tower off-line should read below 2

psig while tower is purging. If excessive purge air is exhausting

during purge cycle, inlet valve may have failed to close or a check

valve may be sticking.

3.2.3.2 Check valves

Check valve sticking will result in excessive air discharge

through a muffler. If excessive air is discharged through the muffler

on the left, check if valve 5a or 5d is sticking. If excessive air is

discharged through the muffler on the right, check if valve 5b or 5c

is sticking.

3.2.3.3 Operating Sequence

For dryers with standard controller and dryers with automatic

purge saving system operating on a fixed time cycle-

Figure 3C and Table 3C show valve sequence times when

dryer is operating on a 10 minute cycle.

Figure 3D and Table 3D

show sequence times when dryer is operating on a four minute

cycle.

TIME (MIN)

0 1 2 3 4

3A OPEN CLOSED

3B CLOSED OPEN

(1) See table 3C for open times.

VALVE

PRESSURE

9A CLOSED CI OPEN CLOSED

6" (

2

)

(2) See table 3D for open times.

3.3 Shut Down

3.3.1 Depressurize dryer

3.3.1.1 Open by-pass valve (if one is installed) and close inlet

and outlet isolation valves.

3.3.1.2 Run timer through a tower change cycle until pressure

gauges on both towers read 0 psig.

3.3.2 De-energize dryer

Turn dryer off using on-off switch (indicating lights extin-

guished).

3.4 Loss of Power

Control valves are designed so that upon loss of power the air

dryer is capable of drying air until the desiccant exposed to the air

flow is saturated.

TABLE 3D Purge valve open times for dryers operating on a 4 minute cycle.

VALVE

FIGURE 3D For dryers operating on a 4 minute cycle

TABLE 3C Purge valve open times for dryers operating on a 10 minute cycle.

FIGURE 3C For dryers operating on a 10 minute cycle

150 psig MWP

100%

66 sec.

90%

59 sec.

80%

53 sec.

70%

46 sec.

60%

40 sec.

50%

33 sec.

40%

26 sec.

30%

20 sec.

250 psig MWP

100%

42 sec.

90%

38 sec.

80%

34 sec.

70%

29 sec.

60%

25 sec.

50%

21 sec.

40%

17 sec.

30%

13 sec.

PRESSURE

ECONOMIZER SWITCH

PURGE TIME

SETTING