12

Track One

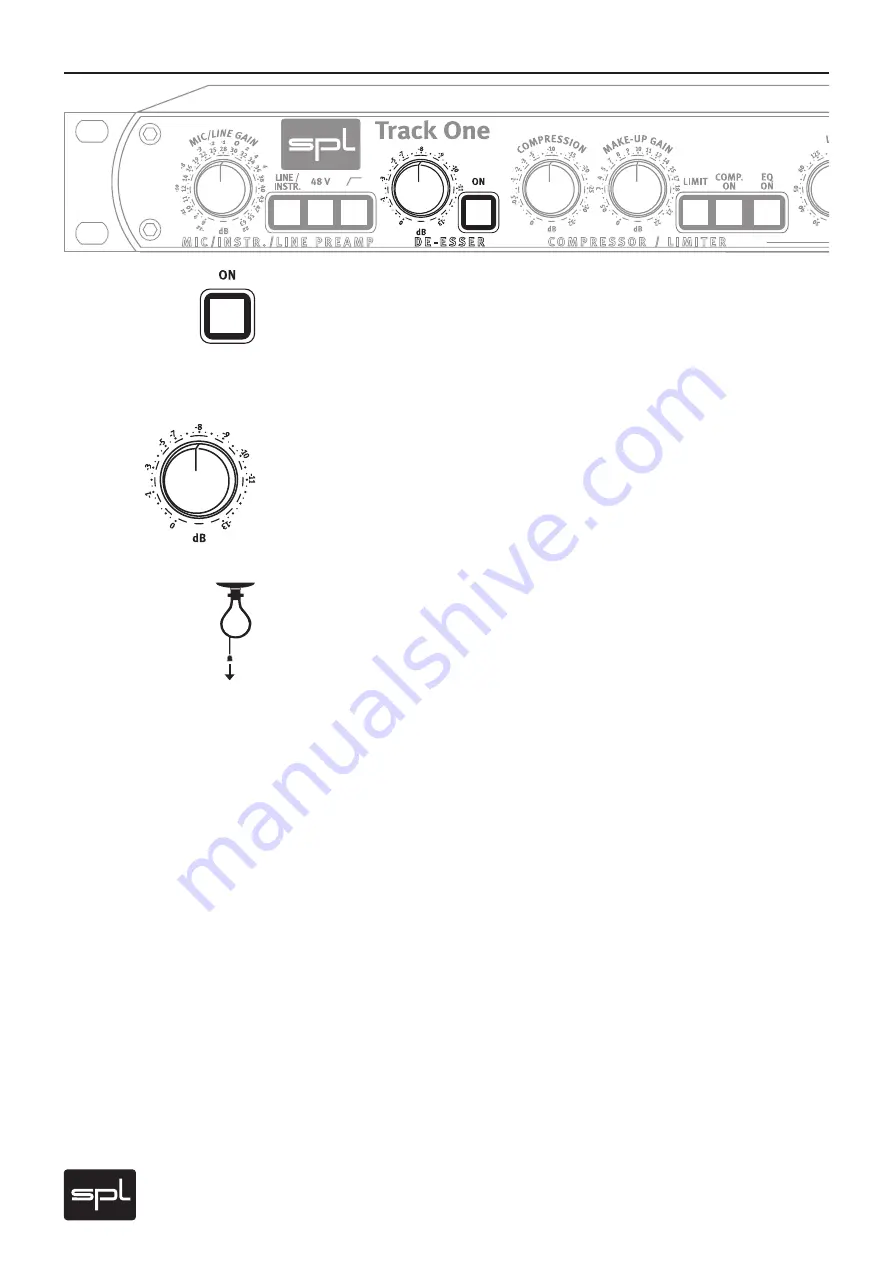

ON

The first processing module is the de-esser, which removes disturbing sibilants when

required. The de-esser module is activated with the ON button. The S-DET. LED in the display

area shows that S-sounds are being detected. It is independent from the De-Esser control

and always informs about detected sibilants – attracting your attention to a possible need for

regulation (also see „S-DET.“ on page 17).

De-Esser control

This control serves to determine the intensity of S-sound reduction. Because processing

is undertaken from comparison with the level of the entire frequency spectrum (see next

section) the processing is more intensive with extreme S-sound levels than with those of

lower levels. This processing method achieves a consistent level of the remaining sibilants in

the output signal.

SPL De-Esser technology

In contrast to common de-essers based upon compressor techniques the SPL De-Esser makes

use of the phase cancellation principle. It employs filters that process only the reducible

“S-frequencies” but do not interfere with the remainder of the spectrum. The S-frequencies

are detected automatically, the phase is inverted and mixed with the original signal. This

method of operation has distinct advantages because it is unobtrusive and helps retain the

original tonal quality. Compressor-typical side effects such as lisping or nasal tones do not

occur. Finally its operation is as simple as pulling on the hand brake.

The reduction is accomplished by comparing the average level with the individual S-sounds:

the de-esser functions only when the S-noise level exceeds the average level of the entire

frequency spectrum. This means for example that original S-sounds with a certain S-portion

are not processed whereas those that are too loud, or do not effectively contribute to the

sound, are reduced – but the character of the voice remains unchanged.

A further specialty is the integrated Auto Threshold function which makes processing indepen-

dent of the input level. Even when the speaker or singer does not maintain a constant distance

to the microphone, processing is retained at the pre-set de-essing value. Conventional

systems are dependent on the input level and work more intensively as the distance to the

microphone is reduced. As a result, the SPL De-Esser does not need to be monitored and

re-adjusted permanently to keep processing constant – and it can always be applied before

the compressor, as changing its position would not be an advantage. That is why an accordant

switching function is not necessary.

Control Elements

De-Esser