9 Repair

NGW 300 / LGW 300 / GBW 300

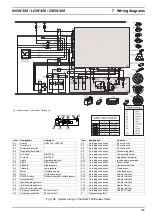

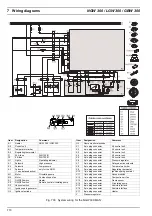

902

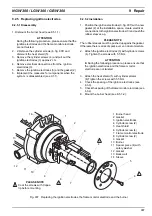

9.1.2.1 Installation of the SG 1585 control unit as a

replacement for the SG 1578 control unit

General information

The SG 1578 control unit for the NGW 300 and LGW 300

heaters is no longer available and was replaced by the

SG 1585 control unit.

The conversion kits consist of the SG 1585 control unit

and he vehicle-specific adapter wiring harness.

Conversion to the SG 1585 control must be carried out in

accordance with the following procedures.

ATTENTION

•

Replacement of the control unit must be done in an un-

energised state. Ignition must be switched off.

•

The sequence of procedures must be followed abso-

lutely so that no fault entries are made in the control

unit and conditionally upon that, as the case my be,

locking the heater is avoided.

(Fault entries are caused at the control unit by open in-

lets and outlets among other things

•

A lock on the heater can only be removed by staff who

have been trained by Spheros.

Implementation

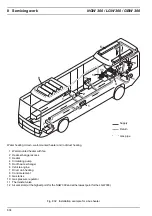

1. Ensure that the heating system is switched off.

Where necessary, switch off the heating system by

activating the main switch, the timer or the aircondi-

tioning system and wait until it stops running.

2. Disconnect the vehicle’s and the control unit’s plugs

from the voltage supply.

3. Where necessary, disconnect the connectors between

the vehicle and the control unit and control lines.

4. Disconnect the connector to the circulating pump.

5. If required, disconnect the connector from the control

unit to the gas pressure regulator.

6. Disconnect the connector plug between the control

unit and the heater.

7. Remove the control unit and retaining spring.

8. Attach the adapter wiring harness to the new control unit.

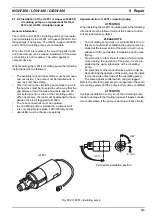

9. Slide the new control unit with a connector to the hea-

ter downwards into the guiding groove of the burner’s

protective hood until it snaps in place in the locking

groove.

10. Attach the connector plug between the adapter wiring

harness and the heater.

11. Attach the connector plug between the adapter wiring

harness and the gas pressure regulator/solenoid.

12. Attach the connector plug between the adapter wiring

harness and the circulating pump.

13. Where necesary, attach the connector plug between the

vehicle (control line) and the adapter wiring harness.

14. Attach the connector plug between the vehicle’s

voltage supply and the adapter wiring harness.

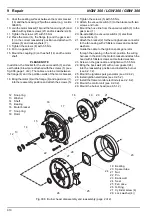

PLEASE NOTE

•

Now, the heating system can be activated by turning

on the main switch, the timer or the airconditioning sy-

stem.

•

After all work has been completed, a trial run must be

carried out (start-up, firing operation, control pause

and after-run).

PLEASE NOTE

Conversion bags for MAN include

the SG 1585 (ID no. 9007655)

without circulation pump monitoring.

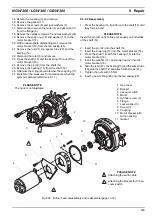

SG 1585 conversion bag for:

Standard (AMP plug)

EvoBus

MAN (AMP-plug)

MAN (Schlemmer plug)

Order no.:

90 058 91B

90 058 92B

90 077 74B

90 058 95B

Fig. 901 Replacement of the SG 1578 control unit by the 1585 control unit

the former

SG 1578 control unit

Available conversion kits

(control unit with adapter wiring harness)

a modified

control unit SG 1585