Speedaire Operating Instructions and Parts Manual

1WC95

Speedaire

®

Permanently Lubricated

Twin Cylinder Air Compressor

E

N

G

L

I

S

H

14

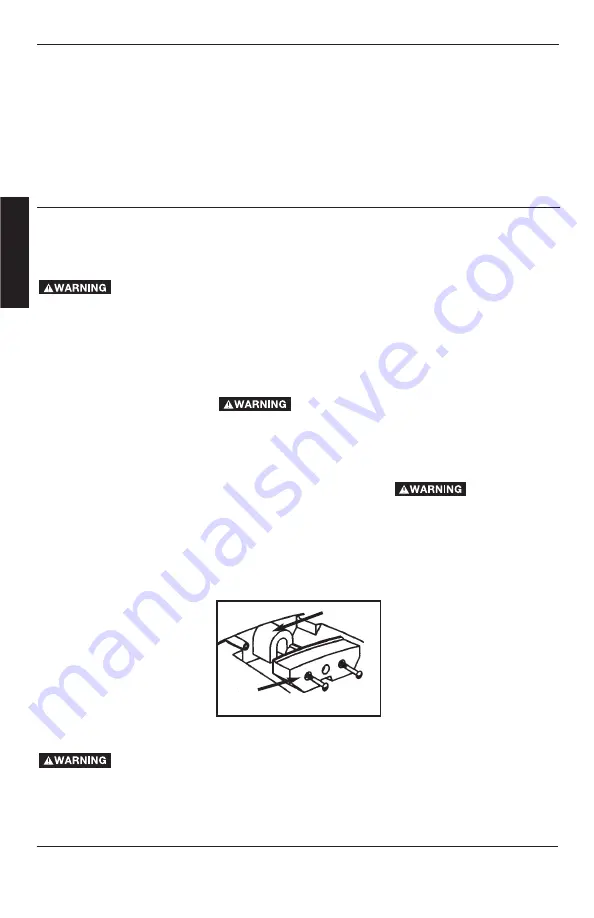

4. Replace air filter and air

filter cover.

NOTE:

If the air filter is

extremely dirty it will need

to be replaced. Refer to the

“Repair Parts” for the cor-

rect part number.

6. After the water has been

drained, close the drain

valve (clockwise). The air

compressor can now be

stored.

NOTE

: If drain valve is

clogged, release all air pres-

sure. The valve can then be

removed, cleaned, and then

reinstalled.

AIR FILTER INSPECTION

AND REPLACEMENT

Hot sur-

faces. Risk of burn.

Compressor heads are

exposed when filter

cover is removed. Allow

compressor to cool prior

to servicing.

A dirty air filter will not

allow the compressor to

operate at full capacity.

Keep the air filter clean at

all times.

1. Remove the air filter

cover.

2. Remove the air filter and

make sure it is clean.

IMPORTANT

: Do not oper-

ate the compressor with the

air filter removed.

3. If dirty, rinse air filter with

warm water and squeeze

dry.

Air Filter

Air

Filter

Cover

AIR COMPRESSOR

PUMP INTAKE AND

EXHAUST VALVES

Once a year have a Trained

Service Technician check the

air compressor pump intake

and exhaust valves.

TO DRAIN TANK

1. Set the On/Auto/Off lever

to “OFF”.

2. Pull the regulator knob

out and turn clockwise to

set the outlet pressure to

zero.

3. Remove the air tool or

accessory.

4. Pull ring on safety valve

allowing air to bleed from

the tank until tank pres-

sure is approximately 20

psi. Release safety valve

ring.

5. Drain water from air tank

by opening drain valve

(counter-clockwise) on

bottom of tank.

Water will

condense in the air tank.

If not drained, water will

corrode and weaken the

air tank causing a risk of

air tank rupture.

Service and

Adjustments

Unit cycles

automatically when

power is on. When doing

maintenance, you may be

exposed to voltage

sources, compressed air

or moving parts. Personal

injuries can occur. Before

performing any mainte-

nance or repair, unplug

the compressor and bleed

off all air pressure.

ALL MAINTENANCE AND

REPAIR OPERATIONS NOT

LISTED MUST BE PER-

FORMED BY A TRAINED

SERVICE TECHNICIAN.

TO REPLACE OR CLEAN

CHECK VALVE

1. Release all air pressure

from air tank. See “To

Drain Tank” in the

Maintenance section.

TO CHECK SAFETY

VALVE

If the safety

valve does not work

properly, over-pressuriza-

tion may occur, causing

air tank rupture or an

explosion.

Before starting compressor,

pull the ring on the safety

valve to make sure that the

safety valve operates freely.

If the valve is stuck or does

not operate smoothly, it

must be replaced with the

same type of valve.

Maintenance

(Continued)

Summary of Contents for 1WC95

Page 77: ...Notes Manuel D utilisation et de Pièces Détachées Speedaire 1WC95 F R A N Ç A I S 23 Fr ...

Page 82: ...Notes Manuel D utilisation et de Pièces Détachées Speedaire 1WC95 F R A N Ç A I S 28 Fr ...

Page 83: ...Notes Manuel D utilisation et de Pièces Détachées Speedaire 1WC95 F R A N Ç A I S 29 Fr ...