SpectraPure

SpectraPure®Inc.

480.894.5437 Call us toll-free 1.800.685.2783

2167 East Fifth St, Tempe, Arizona 85281

®

12

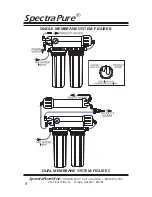

1. Locate the yellow concentrate tubing (Fig. B for Single-Membrane System or

Fig. C for Dual-Membrane System). Remove the tubing from its push-fitting

at the membrane:

a.) Firmly depress and hold the push-fitting collar down with your

thumbnail.

b.) While the push-fitting collar is depressed, pull the tubing straight

out of the push-fitting. Once the tubing is removed, release the

collar.

2. Carefully remove the flow restrictor assembly, now visible as a plastic insert In

the end of the yellow tubing (Fig. D). You may use an object such as a dull

knife to help pry the flow restrictor insert from the end of the tubing. The

entire flow restrictor (consisting of the insert collar and thin capillary tubing)

may then be gently extracted.

Note: Take care not to crush or otherwise damage the delicate

capillary tubing

.

3. Using a new single-edge razor blade, carefully measure and then cut the

flow restrictor as instructed.

4. Re-insert the flow restrictor assembly into the yellow tubing and firmly

re-seat the insert into the end of the yellow tubing by carefully pressing on

the insert with your thumbnail. Care should be taken not to crush or

other-wise damage the end of the capillary tubing protruding from the end

of the insert.

FLOW RESTRICTOR REMOVAL, ADJUSTMENT

AND REPLACEMENT