5

08/06

ID# M867SF12

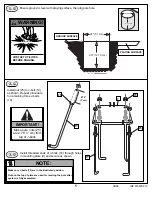

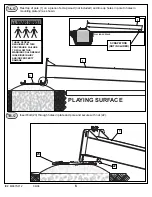

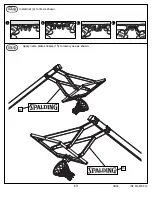

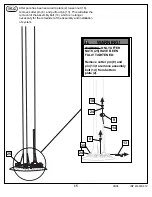

Ensure ground is level with playing surface, then dig pole hole.

Install threaded ends of J-bolts (19) through holes

in mounting plate (2) and secure as shown.

2

25

25

25

19

19

Install nut (25) to J-bolt (19)

as shown. Repeat procedure

for remaining three J-bolts

(19).

2.75”

(7 cm)

CONTACT UTILITIES

BEFORE DIGGING.

WARNING!

24" (61 cm)

48" (121.9 cm)

PLAYING SURFACE

GROUND SURFACE

24" (61 cm)

48" (121.9 cm)

IMPORTANT!

Make sure nuts (25)

are 2.75” (7 cm) from

top of J-bolts

Make sure J-bolts (19) are in the illustrated position.

Nuts on the top of plate are used for leveling the pole after

system is fully assembled.

NOTE:

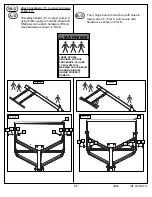

1.

3.

2.