12

NOTICE: It is a requirement of the International

Mechanical Code (307.2.3) to install a secondary drain

or an auxiliary drain pan where damage to any building

components will occur as a result of overflow from the

equipment drain pan or stoppage in the condensate

drain piping from a cooling or an evaporator coil.

Follow local code requirements

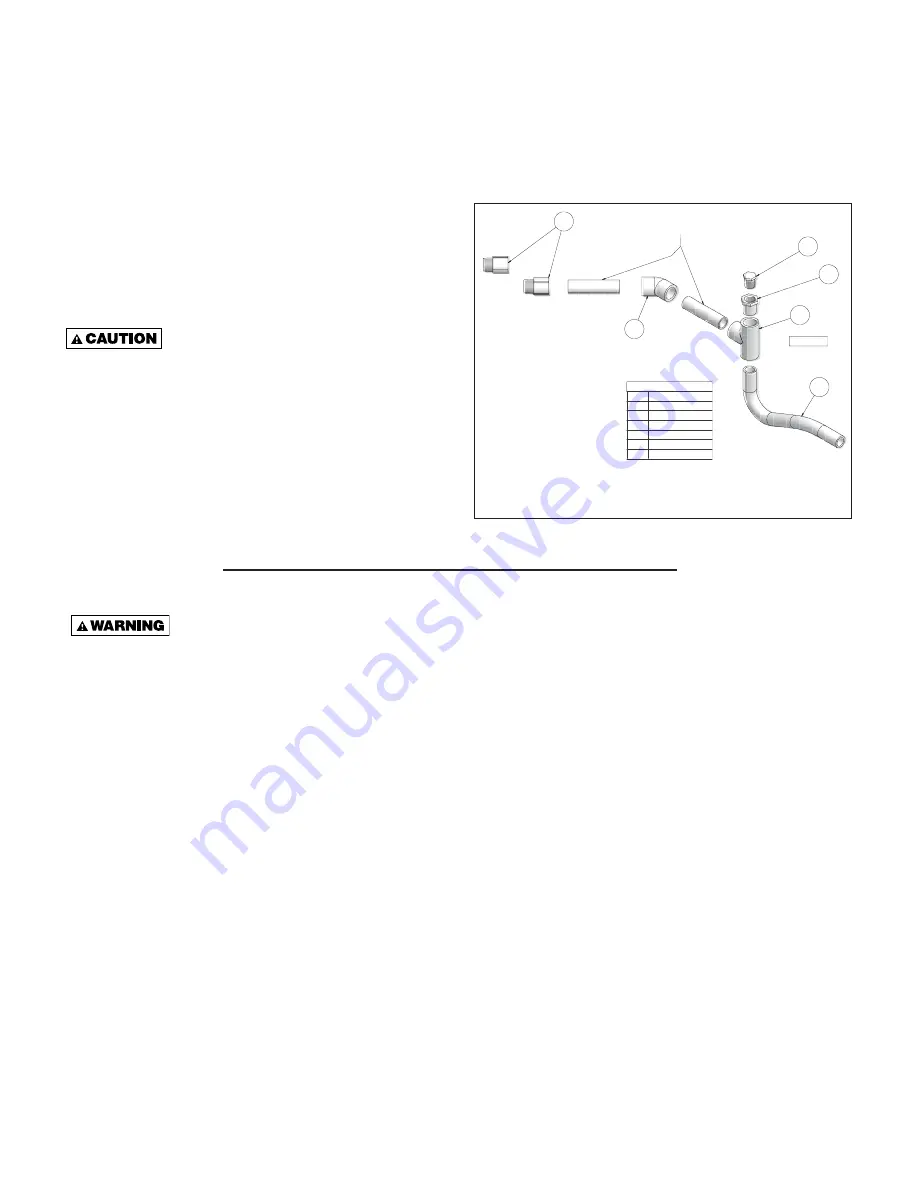

Refer to Fig. 2.2 for primary and secondary condensate

drain locations. Components for the PVC condensate

trap are provided in a separate bag with fan coil unit (see

Fig. 2.12) and should be cemented together with PVC

pipe cement.

Do not use substitute trap. Do not cut

off or alter trap components.

Screw male adapter (see Fig. 2.12) into unit’s primary

condensate drain connection. Assemble and cement

remaining components together. Then cement assembly

to male adapter. The 45° elbow provides an offset from

beneath unit suction line for access to clean-out plug.

Run a condensate line from the trap to a suitable drain

that’s in accordance with local codes. Make sure the line

is pitched

1

⁄

4

" per foot.

NOTICE: The secondary drain connection requires

field supplied components to complete installation.

Follow local code requirements.

NOTICE: Never connect condensate line to a closed

drain system.

STEP 6: INSTALLING THE CONDENSATE TRAP & LINE

ITEM

1

2

3

4

5

6

MALE ADAPTER, 3/4''

DESCRIPTION

ELBOW 45

????

, 3/4''

1/2'' PLUG

3/4'' X 1/2'' BUSHING

TEE, 3/4''

P-TRAP, 3/4''

3/4'' P-TRAP ASS'Y KIT

WG0127B

NOTE: PIPE SECTIONS ARE FIELD SUPPLIED.

1

2

3

5

4

6

SEE NOTE

SECOND 3/4" MALE ADAPTER SUPPLIED FOR OVERFLOW CONN ECTION

*

*

FIGURE 2.12: CONDENSATE TRAP ASSEMBLY

STEP 7: WIRING THE UNIT

All electrical and control wiring must be installed in

accordance with the codes listed in Section 1 of this

manual. Wiring diagram is provided in Figure 2.13. A

separate 208-230/60/1 power supply is recommended for

the unit. Use standard 15-amp fuse and 16-gauge wire

from power supply to unit.

Connect power supply to Terminals L1 and L2 on the high

voltage terminal block. Connect a ground wire to the

equipment ground terminal located next to the high volt-

age terminal block.

Turn off electrical power supply

before servicing. Contact with live electric compo-

nents can cause shock or death.

The low voltage transformer in the unit has a 208 volt tap

in the primary winding (color coded RED). If unit is to be

operated with 208 volt electrical service, remove the 230

volt ORANGE lead from the L2 terminal and connect the

208 volt RED lead to the L2 terminal. Be sure to insulate

the end of the unused ORANGE lead.

Locate the room thermostat on a wall near the return air

box, between 40" to 48" from the floor. Connect the low-

voltage thermostat wiring from the room thermostat to the

low voltage control block in the unit.

Connect low voltage from air handler to condensing unit

as shown in figure 2.13.

Set DIP switches according to application. See page 14,

SpacePak G Series Control DIP switch settings.

STEP 8: INSTALLING AIR DISTRIBUTION COMPONENTS

All plenum duct and supply tubing runs as well as room

terminator locations must be in accordance with air

distribution system requirements listed in Section 1 of

this manual. Where taping of joints is required, UL181

approved tape is required.

Plenum Duct Installation

All tees, elbows and branch runs must be a minimum of 24"

from the fan coil unit or any other tee, elbow or branch run.

Keep all tees and elbows to a minimum to keep system

pressure drop on larger layouts to a minimum.

NOTICE: Refer to duct installation instructions sup-

plied with fan coil unit or follow manufacturers

instructions supplied with other duct system types.

Summary of Contents for ESP-G SYSTEM

Page 10: ...10 FIGURE 2 9 FIGURE 2 8...

Page 13: ...FIGURE 2 13 WIRING DIAGRAM 13...