12

Southworth Products

FPS3000-43NFO-21/27 Manual

5. Operation

5.1 To Raise and Lower

There are two buttons located on both sides of the handle. The inside one is for lowering the forks.

The outside one is for raising the forks. When operating, always make sure the load being lifted

is within the loading capacity of your stacker and the load has been stacked safely on the pallet.

Also, make sure that the length of the forks corresponds to the length of the pallet. In this way, the

load rollers will place themselves in the opening at the end of the pallet, so that when you raise

the forks, you will not break the bottom boards of the pallet. Always make sure that when entering

the pallet that the forks are in the fully lowered position. Be careful when lifting pallets that are too

short or too long for the stacker. It might destroy your pallet by breaking the bottom boards, and

if the forks project through the end of the pallet, the tips of fork may go into the next pallet that is

behind the pallet that you are lifting, which may bend the tips of forks and overload the capacity of

the stacker.

5.2 Travel Function

To travel, rotate the butterfly controls throttle on the upper part of the handle. When rotating the

butterfly control towards the forks, the stacker runs forwards in the forks first direction. When

rotating the butterfly towards the operator, the stacker runs in the reverse direction. Always make

sure the stacker clears any obstruction when traveling, and that your path of travel is clear of

people. Never carry loads above the loading capacity of the stacker. It is suggested that when

traveling without a load, the forks be in the lowered position. The speed of the stacker is increased

by the degree of the rotation in either direction; it functions like a throttle. W hen you release your

hand from the butterfly control, it automatically will resume to the neutral position and the speed of

the stacker will slow down, and come to a stop.

5.3 Turtle Speed Travel

When the butterfly control is engaged forward (toward the forks) or reverse (toward the operator

if the operator simultaneously engages the turtle speed button the forward and/or reverse speed

is limited to 50% of full speed or turtle speed. The operator can engage the butterfly forward with

the right hand and engage the turtle speed button with the left hand. The operator can engage

the butterfly forward with the left hand and engage the turtle speed button with the right hand. The

reverse operation is also controlled with either hand. The turtle speed is maintained only when the

turtle speed button is engaged. When the turtle speed button is not engaged the unit will operate

at full speed. The turtle speed button is a maintained contact operation.

Turtle Speed

Summary of Contents for Stack-N-Go FPS3000-43NFO-21

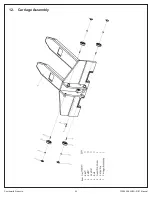

Page 18: ...18 Southworth Products FPS3000 43NFO 21 27 Manual 8 Stacker Body Components...

Page 19: ...19 Southworth Products FPS3000 43NFO 21 27 Manual 9 Control Pod 9 1 August 2018 and Prior...

Page 20: ...20 Southworth Products FPS3000 43NFO 21 27 Manual 9 2 September 2018 to Present...

Page 22: ...22 Southworth Products FPS3000 43NFO 21 27 Manual 10 2 September 2018 to Present...

Page 28: ...28 Southworth Products FPS3000 43NFO 21 27 Manual 16 Hydraulic Schematic...

Page 31: ...31 Southworth Products FPS3000 43NFO 21 27 Manual...

Page 32: ...32 Southworth Products FPS3000 43NFO 21 27 Manual 18 2 November 2017 to Present...

Page 33: ...33 Southworth Products FPS3000 43NFO 21 27 Manual...