11

Southworth Products

FPS3000-43NFO-21/27 Manual

4. Setup

4.1 Inspection

Upon receipt of the stacker, inspect the equipment completely to determine if there is any shipping

damage, and that the lift is complete. Southworth tests and inspects every piece of equipment

prior to shipment. If damage is apparent, a freight claim must be filed with the freight company.

Do not use the stacker if there appears to be any damage. With the stacker in a lowered position,

check the following:

• Check for signs of damage especially to the back cabinet that houses the battery, electrical/

hydraulic power pack.

• Check all electrical and hydraulic connections for tightness.

• Remove back panel.

1. Turn key switch to “OFF” position.

2. Push in E-stop and unscrew the red knob.

3. Lift off back panel. There is enough wire to the key switch to allow the panel to be set aside.

• Inspect for any bent or damaged parts.

4.2 Removing From Pallet

Each of the Southworth stackers is shipped out on a pallet or skid. Prior to removing the unit from

the pallet or skid, remove all tie down straps and packaging. Visually inspect the unit as closely as

possible.

With an overhead hoist or forklift, carefully pick up the unit taking into consideration the center

of gravity of the unit. If you choose to pick the unit with an overhead hoist, use a nylon sling and

hoist with a minimum of 2,000-lb. capacity. The nylon sling will not do any damage to the steel

construction of stacker. Pick the unit up. On conventional masts use the top cross-member of the

lift. On narrow masts the cover must be removed to access lifting equipment. Be careful of the

stacker swinging once fully lifted off the pallet or skid. Have all personnel completely cleared from

the area.

Pick the unit up approximately six inches above the pallet or skid. Once raised, remove the pallet

or skid from below the lift. Do not move the lift around in the air. Lower the stacker on the ground.

4.3 Preparation For Use

This stacker left our factory in new condition. It has been inspected and weight tested to assure all

performance standards have been met.

Visually inspect the stacker for damage. Check for attachments and accessories that may

have been ordered. If there is any damage or missing parts, report it to your carrier and your

Southworth dealer immediately.

Remove all metal/plastic bands, cardboard and other material used for shipping purposes.

Check to see if chains are in place, and that the lift system is in working order. Inspect for oil leaks.

Connect battery cable. Check cables and wires on battery charger as well as battery.

Summary of Contents for Stack-N-Go FPS3000-43NFO-21

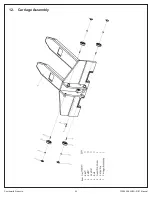

Page 18: ...18 Southworth Products FPS3000 43NFO 21 27 Manual 8 Stacker Body Components...

Page 19: ...19 Southworth Products FPS3000 43NFO 21 27 Manual 9 Control Pod 9 1 August 2018 and Prior...

Page 20: ...20 Southworth Products FPS3000 43NFO 21 27 Manual 9 2 September 2018 to Present...

Page 22: ...22 Southworth Products FPS3000 43NFO 21 27 Manual 10 2 September 2018 to Present...

Page 28: ...28 Southworth Products FPS3000 43NFO 21 27 Manual 16 Hydraulic Schematic...

Page 31: ...31 Southworth Products FPS3000 43NFO 21 27 Manual...

Page 32: ...32 Southworth Products FPS3000 43NFO 21 27 Manual 18 2 November 2017 to Present...

Page 33: ...33 Southworth Products FPS3000 43NFO 21 27 Manual...