MAINTENANCE

South Bend Tools

For Machines Mfd. Since 12/20

Model SB1117

-33-

M A I N T E N A N C E

Maintenance Schedule

For optimum performance from this machine,

this maintenance schedule must be strictly

followed.

Ongoing

• Check/correct loose mounting bolts.

• Check/replace damaged sanding belt.

• Check/replace worn switch.

• Check/replace worn or damaged wires.

• Clean/protect table.

• Correct any other unsafe condition.

Monthly

• Lubricate oscillation grease fittings.

• Clean/vacuum dust buildup from inside

cabinet and belt guard and off motor.

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

Cleaning & Protecting

Figure

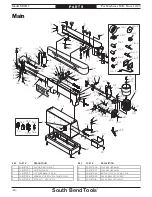

Figure 55. Location of oscillation grease fittings.

. Location of oscillation grease fittings.

Bare metal surfaces can quickly develop surface

rust if not coated. Machinery stored near

windows in direct sunlight or where paints,

thinners, or certain gasses are open to the air

can experience bleaching, discoloring of paint or

yellowing of clear plastic guards.

Cleaning the SB1117 is relatively easy. Vacuum

excess wood chips and sawdust, and wipe off the

remaining dust with a dry cloth. If any resin has

built up, use a resin-dissolving cleaner to remove

it.

Protect the unpainted cast iron table by wiping

it clean after every use

—

this ensures moisture

from wood dust does not remain on bare

metal surfaces. Keep the tables rust-free with

regular applications of products like G96® Gun

Treatment, SLIPIT®, or Boeshield® T-9 (see

Page 32 for more details).

Machine Storage

All machinery will develop serious rust or

corrosion damage if it is not properly prepared

for storage. If decommissioning this machine,

disconnect all power sources, thoroughly clean

bare metal surfaces, coat them with light weight

grease or rust preventative, and cover machine

with a tarp or plastic sheet to keep out dust.

Lubrication

The oscillation grease fittings shown in Figure

55 should be lubricated once every 50 hours of

operation with a thin coat of light machine oil

and 1

–

2 pumps of NLGI #2 or Syn-O-Gen grease.

Grease

Grease

Fittings

Fittings

T26419—Syn-O-Gen Synthetic Grease

Formulated with 100% pure synthesized

hydrocarbon basestocks that are compounded

with special thickeners and additives to

make Syn-O-Gen non-melt, tacky, and water-

resistant. Extremely low pour point, extremely

high temperature oxidation, and thermal

stability produce a grease that is unmatched in

performance.

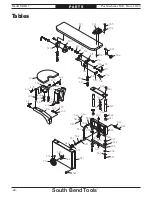

Figure

Figure 56. Model T26419 Syn-O-Gen Synthetic

. Model T26419 Syn-O-Gen Synthetic

Grease (NLGI #2 equivalent).

Grease (NLGI #2 equivalent).