South Bend Tools

For Machines Mfd. Since 12/20

Model SB1117

-31-

O P E R A T I O N

Figure

Figure 49. Typical contour sanding operation.

. Typical contour sanding operation.

Bevel Sanding

Bevel sanding can take place on either the main

table or the end table on the Model SB1117.

Adjust the table tilt to match the angle you wish

to sand on a workpiece. Regardless of the table

being used, always keep the workpiece against

the table and use two hands to control it.

To bevel sand:

1.

Set table tilt to match angle of bevel on

workpiece, and set main table height to

match workpiece thickness.

2.

Connect machine to power, turn it ON, and

allow it to reach full speed.

3.

Support workpiece with table (and miter

gauge or back stop if operation allows), and

slowly feed workpiece into moving belt with

light, even pressure (see Figures 50

–

51. DO

NOT force workpiece against belt.

To contour sand:

1.

Open end table dust hood.

2.

Raise end table to desired height and

adjust table tilt to desired setting (refer to

Adjusting End Table on Page 28).

3.

Connect machine to power, turn it ON, and

allow it to reach full speed.

4.

While securely holding workpiece, slowly

feed workpiece into moving belt with

light, even pressure. Maintain control of

workpiece, as shown in Figure 49. DO NOT

force workpiece against belt.

Contour Sanding

Contour sanding operations are performed on the

end table with the workpiece pressing against

the idler wheel sanding drum. Always use two

hands to maintain best control.

Do not contour sand without end table

properly installed or serious personal injury

could result.

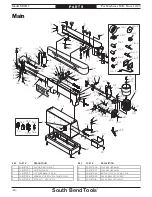

Figure

Figure 50. Bevel sanding operation example.

. Bevel sanding operation example.

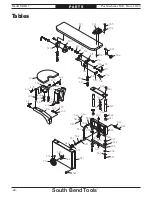

Figure

Figure 51. Bevel contour sanding operation example.

. Bevel contour sanding operation example.