Page 22 / 22

Assembly instructions

Compact-Line kit

www.sorotec.de

V 2.1.0

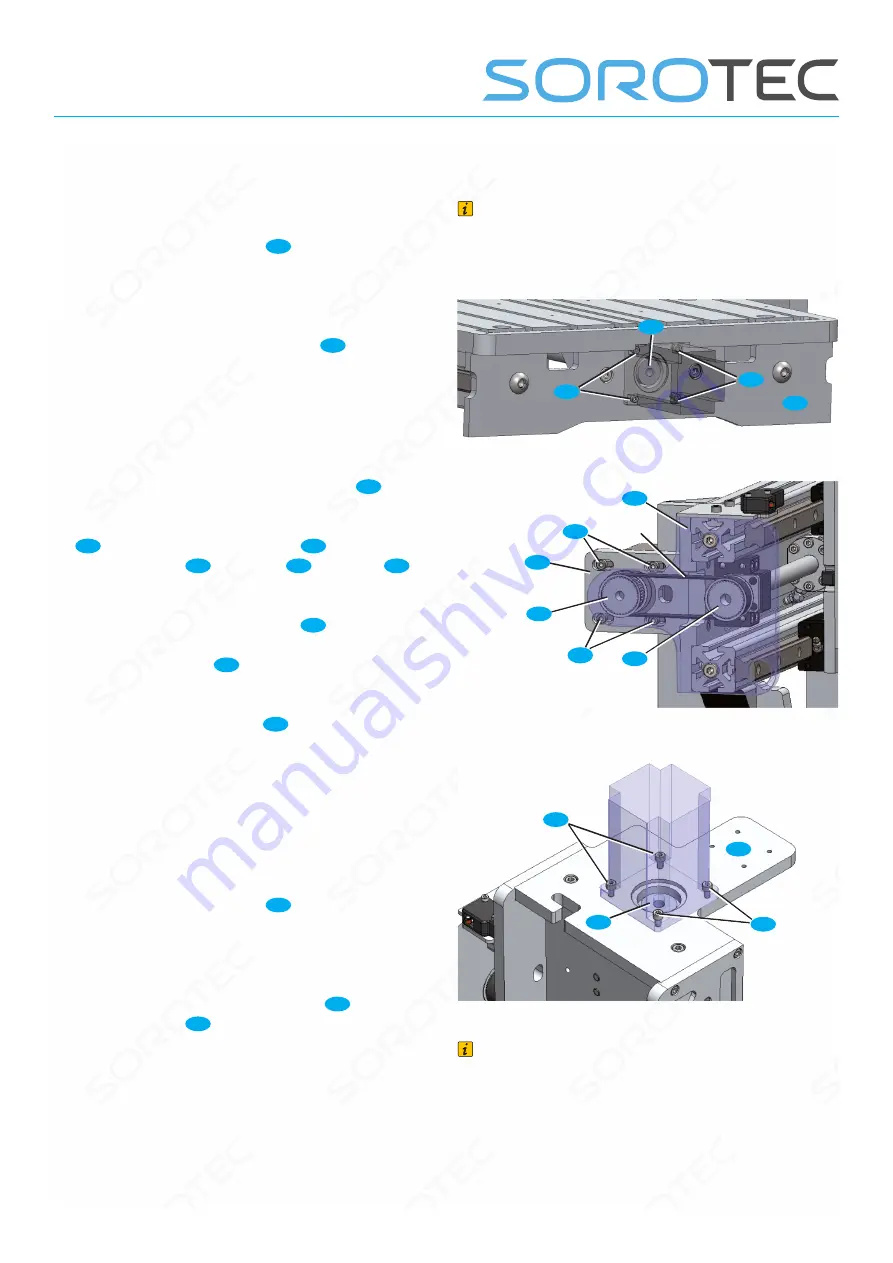

Assembly of the axis drives

X axis

• Push the claw coupling

13

as far as possible

onto the shoulder of the ball screw and fix it with

the locking screw.

• Insert the stepper motor into the claw coupling

and screw it to the rear end plate

28

.

• Fix the stepper motor with the safety screw of

the claw coupling.

Y axis

• Temporarily remove end plate Y left

2

.

•

Screw the stepper motor to the motor flange Y

19

(either with M5x25 screws

C5

OR with

M4x16 screws

B2

, washers

V

and nuts

K

);

Slightly counter-tighten the screws.

• Push the toothed belt wheel

35

onto the

output shaft of the stepper motor, align it with the

toothed belt wheel

36

on the ball screw and fix it

with the locking screw.

• Put on the toothed belt

34

and tension it by

moving the stepper motor; Tighten the stepper

motor mounting screws.

• Screw the end plate Y left back to the portal

beam.

Z axis

• Push the claw coupling

13

as far as possible

onto the shoulder of the ball screw and fix it with

the locking screw.

• Insert the stepper motor into the claw coupling

and screw it to the motor flange Z

20

using

M4x16 screws

B2

.

• Fix the stepper motor with the safety screw of

the claw coupling.

Note

The stepper motors shown below are not part of

the scope of delivery. The illustration is intended

to clarify the structure of the axis drives.

Fig. 30: Assembly stepper motor X axis

Fig. 31: Assembly stepper motor Y axis

Fig. 32: Assembly stepper motor Z axis

Note

Claw couplings can cause loud noises during

operation. In this case, lubricate the plastic buffer

with a little Vaseline. Never use normal grease

or lubricating oil! Ordinary lubricants attack the

plastic and can destroy it.

13

B2

B2

28

35

2

C5

19

C5

36

20

B2

13

B2