4

SCD-C222ES

The laser diode in the optical pick-up block may suffer electro-

static break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emis-

sion, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

CLEANING OF OPTICAL PICK-UP LENS

In cleaning the lens of optical pick-up, use the air blower.

Never use a cotton swab for cleaning the lens of optical pick-up,

which otherwise causes a trouble.

CHECKING SIGNALS OF CD SECTION

Efficiency to check each signal of CD section is increased when

the test points on the MAIN board are used.

Refer to 5-8. WAVEFORMS CHECK (page 27)

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

SECTION 1

SERVICING NOTES

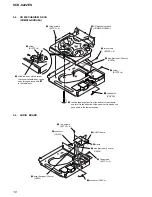

table

tapering driver

*

To close the disc table, turn the tapering

driver in the reverse direction (to IN direction).

HOW TO OPEN THE DISC TABLE WHEN POWER

SWITCH TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and

turn it in the direction of the arrow (to OUT direction).

Summary of Contents for SCD-C222ES - Es Series 5 Disc

Page 99: ...99 SCD C222ES MEMO ...