4-13

SAL1680Z (Vario-Sonnar DT 3.5-4.5/16-80 ZA) (Vario-Sonnar T

*

DT 16-80mm F3.5-4.5 ZA)

4-2.

APERTURE DIAMETER CHECK/ADJUSTMENT

4-2-1. Aperture Diameter Check

Equipment

• Luminance Box

• Camera DSLR-A100

• AE Master Lens

• Compact Flash (CF) Card (For image saving)

• Personal Computer (PC)

(Color Calculator 2 installed)

1. Preparations

1)

Install the CF card to the camera.

2)

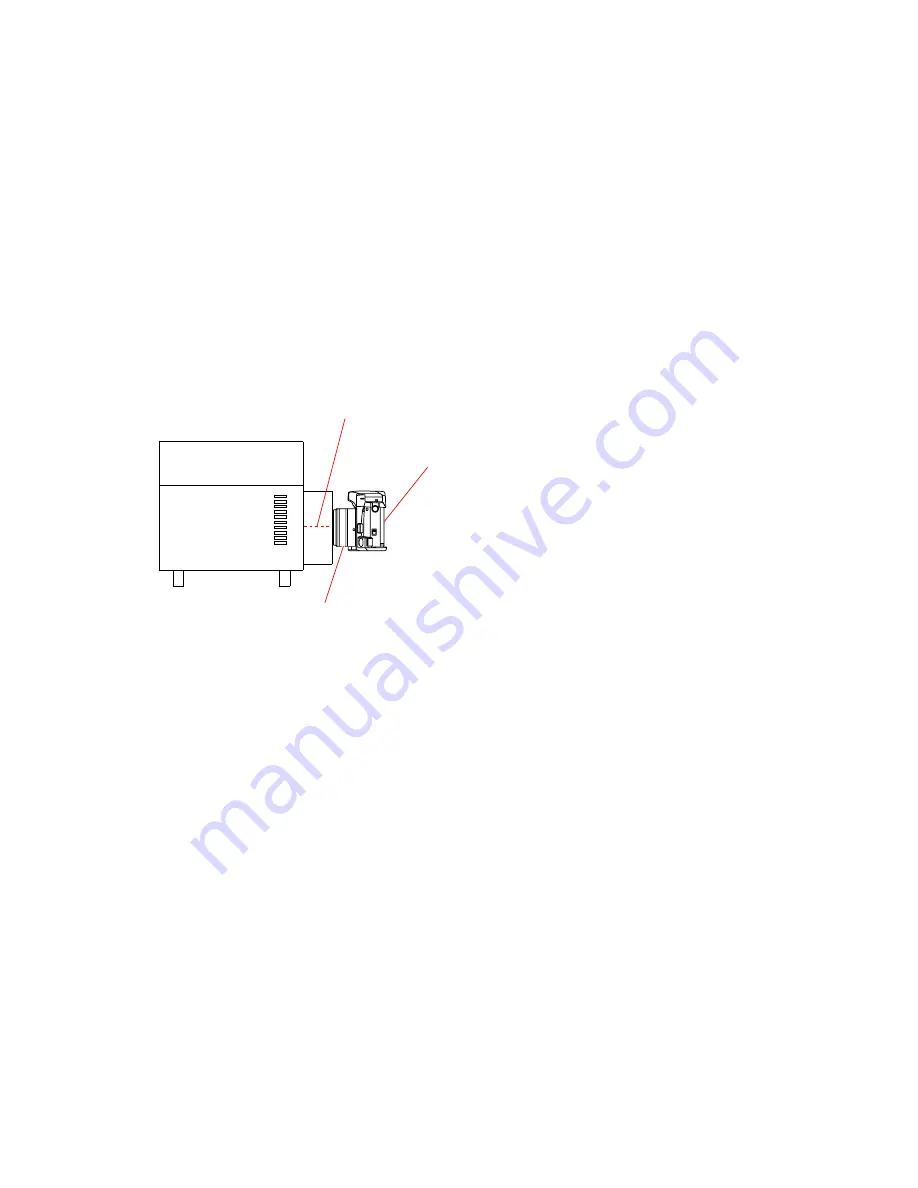

Set the equipments, camera and master lens as shown in Fig.4-2-1.

Fig.4-2-1

3)

Shoot the images under the following conditions and save them.

Note:

Shoot the center of the luminance surface three times with the master lens and checking lens.

Setting of Luminance box:

Luminance:

EV12

Setting of Lens:

Zoom:

Wide end (focal length: 16mm)

Focus:

Infinity end

Setting of Camera:

ISO:

100

Exposure Mode:

M

shutter Speed:

1/125

Aperture:

F5.6

Focus Mode:

MF

Metering:

Center weighted

Preset white balance: Tungsten

D-R:

OFF

Luminance box

Luminance: EV12

Camera

ISO: 100

Exposure Mode: M

Shutter Speed: 1/125

Aperture: F5.6

Focus Mode: MF

Metering: Center weighted

Preset white balance: Tungsten

D-R: OFF

Master lens or checking lens

Zoom: Wide end (focal length: 16mm)

Focus: Infinity end

Shoot the center of the luminance surface