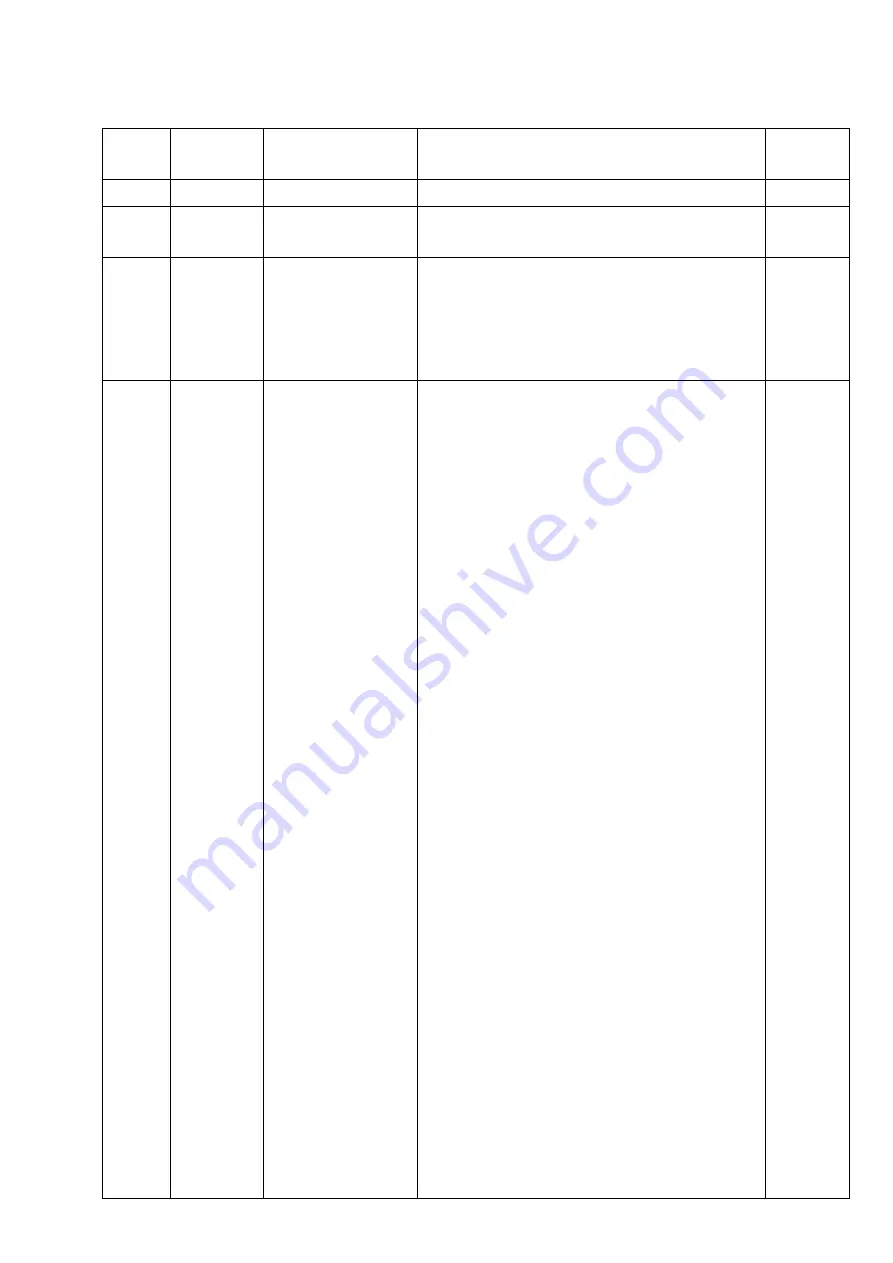

Revision History

SAL135F28 (STF 2.8(T4.5)/135) (135mm F2.8 [T4.5] STF)

Ver.

1.0

1.1

1.2

Date

2006.10

2006.11

2007.01

History

Official Release

Correction-1

(C1)

Revised-1

Contents

—

• Correction of Repair Parts

S.M Correction :

• Change of Repair Parts

• Change of List of Service Tools and

S.M. Rev.

issued

—

Yes

Yes

985211513.pdf