7-3

2-3.

SERVO SYSTEM CHECK

Unless otherwise specified, set the switches to the following

positions.

•

CHANNEL

switch ..................................................... LINE

•

TAPE SPEED

switch ......................................................... SP

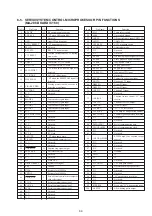

2-3-1. RF Switching Position Adjustment

(MA-286, RP-217 Boards)

[Adjustment Purpose]

To adjust the link of the A-ch and B-ch of the tape playback outputs.

To make the unit compatible with other tapes and units. If this

specification is not satisfied, the link will appear on the screen and

the screen will be disrupted, etc.

Mode

Playback

Signal

Alignment tape: SP color bar portion

Measurement point

CH1: Video LINE OUT (EURO)

CH2: CN261 pin

2

(RF SWP)

Measuring instrument

Oscilloscope

Specified value

6.5 ± 0.5H (416 ± 32

µ

sec)

[Adjustment Method]

1)

Short-circuit between CN261 pin

5

and pin

3

on RP-217

board for about 1 second to activate the RF switching position

adjustment mode.

2)

Check that “ADJ-RF” is indicated on FL display.

3)

Using the c and – buttons, adjust to 416 ± 32

µ

sec (6.5

± 0.5H).

4)

Press the PAUSE button.

5)

Press the EJECT button.

Fig. 7-2-3.

2-4.

VIDEO SYSTEM CHECKS AND ADJUSTMENT

For the video system checks, follow the checking procedures given

below as a rule. The color bar video signal supplied from the pattern

generator is used as the video input signal for the video system

adjustment of the recording mode. Check that the signal satisfies

the specified value designated in the “Check of input signal” (Fig.

7-2-2)

Unless otherwise specified, set the switches to the following

positions.

•

CHANNEL

switch .................................................. LINE 1

•

TAPE SPEED

switch ......................................................... SP

[Checking Sequence]

1)

X’tal OSC Check

2)

SYNC AGC Check

3)

White clip/Dark clip Check

4)

Recording Y Level Check

5)

Recording Chroma Level Check

6)

Playback Level Check

7)

VCO frequency adjustment

2-4-1. X’tal OSC Check (MA-286 Board)

Mode

Playback

Signal

Alignment tape: SP Color bar portion

Measurement point

IC201 pin

%•

Measuring instrument

Oscilloscope and Frequency counter

Specified value

4,433,619 ± 96Hz

Note:

A frequency counter should be connected through a buffer

amplifier (oscilloscope, etc.) having a high impedance and

a low capacitance.

[Check Method]

1)

Check that the oscillation frequency satisfies the specified value

and that the oscillation voltage is 500 ± 200mVp-p.

Fig. 7-2-4.

500

±

200mVp-p

4,443,619

±

90Hz