5-33

CCD-TRV107E/TRV108E/TRV208E/TRV408E

3-2. SYSTEM CONTROL SYSTEM ADJUSTMENT

1. Initialization of D, E, F, 7 Page Data

If the D, E, F, 7 page data is erased due to some reason, perform “1-

2. INITIALIZATION OF D, E, F, 7 PAGE DATA”, of “5-1.

CAMERA SECTION ADJUSTMENT”

3-3. SERVO ADJUSTMENT

1. CAP FG Offset Adjustment (VC-272 board)

Set the Cap FG signal duty cycle to 50% to establish an appropriate

capstan servo. If deviated, the uneven rotation of capstan and noise

can occur in the LP mode.

Mode

Camera recording (SP mode)

Subject

Arbitrary

Measurement Point

CAP FG (Pin

4

of CN713)

Measuring Instrument

Oscilloscope

Adjustment Page

F

Adjustment Address

59

Specified value

Duty = 50 ± 1 %

Adjusting method:

Order Page Address Data

Procedure

1

0

01

01

Set the data.

2

6

01

81

Set the data, and press PAUSE

button.

3

6

02

Check that the data changes to

“01”.

4

6

01

00

Set the data, and press PAUSE

button.

5

Check that Duty of CAP FG signal

satisfies the specified value. If not,

repeat steps 2 to 5.

6

0

01

00

Set the data.

2. Switching Position Adjustment (VC-272 board)

If deviated in this case causes switching noise or jitter on the played

back screen.

Mode

Playback

Signal

Alignment tape:

For tracking adjustment

(WR5-1CP)

Measurement Point

CH1: SWP (Pin

5

of CN713)

CH2: PB RF (Pin

9

of CN713)

Measuring Instrument

Oscilloscope

Adjustment Page

F

Adjustment Address

5A, 5B

Specified Value

t1 = 0 ± 10

µ

sec

Adjusting Method:

Order Page Address Data

Procedure

1

0

01

01

Set the data.

2

F

20

40

Set the data, and press PAUSE

button.

3

F

5A

Change the data and minimize

“t1”. (Coarse adjustment)

4

F

5A

Press PAUSE button

5

F

5B

Change the data and adjust so

that the switching position (t1)

becomes the specified value.

(Fine adjustment)

6

F

5B

Press PAUSE button

7

F

20

00

Set the data, and press PAUSE

button.

8

0

01

00

Set the data.

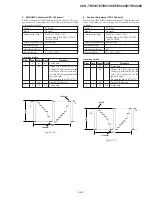

RadarW

RadarW

RadarW

A

B

Duty = A/B

×

100 [%]

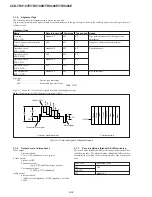

Center of movement

CH1

CH2

Enlargement

t1=0

±

10

µ

sec

CH1

CH2

Fig. 5-3-4.

Fig. 5-3-5.