6

DVP-CX777ES

SECTION 1

SERVICING NOTES

The laser diode in the optical pick-up block may suffer electro-

static break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emis-

sion, observe from more than 30 cm away from the objective lens.

NOTE OF REPLACING THE MB BOARD

When replacing the MB board, since the adjustment value is not

set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1. Set the test mode. (See page 23)

2. Press the

[2]

key of the remote commander, and set the “DRIVE

MANUAL OPERATION”. (See page 29)

3. Press the

[6]

key of the remote commander, and set the “2-6,

Memory Check”. (See page 32)

4. Press the

[CLEAR]

key of the remote commander, and initial-

ize Memory.

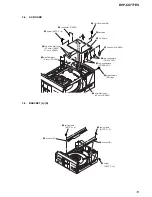

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

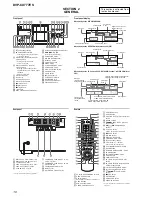

CHECK OF POWER BOARD WITH THE POWER ON

It is possible to analyze the defect with only POWER board power

ON.

Procedure:

1. Set to power OFF state.

2. Remove the connector from CN201 on the POWER board.

3. Short between CN201 pin

1

(P-CONT) and CN201 pin

qa

(EVER+3.3V) on the POWER board.

4. Turn the power ON.

5. Confirm that the voltage value of CN201 each pin on the

POWER board satisfy following value .

CN201 Pin

Voltage Value

pin

2

(EVER–11V)

–11V

pin

3

(SW–11V)

–11V

pin

6

,

7

(SW+11V)

+11V

pin

8

(SW+3.3V)

+3.3V

pin

qa

(EVER+3.3V)

+3.3V

pin

qs

(SW+5V)

+5V

pin

qd

(EVER+5V)

+5V

– POWER Board (Conductor Side) –

CN201

13

1

Ver 1.1