– 18 –

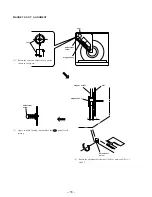

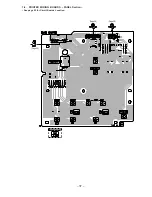

cam

adjustment

screw

magnet ass’y

cam

adjustment

screw

magnet holder

disc

magnet ass’y

adjustment

screw

A

B

MAGNET ASS’Y ALIGNMENT

(1)

Rotate the cam and adjust to the position

shown in the figure.

(2)

Rotate the adjustment screw until A=B or between A:B=2:1

and 1:2

(3)

Apply suitable locking compaund to the part after ad-

justing.

1234

1234

1234