Art.-Nr. 908.30.62.00

Stand 11/2015

- 24 -

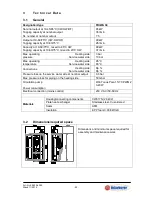

3.3

Pressure loss/pump characteristic curve

Tuxhorn - KRce

21.10.2015

Druckverlust

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

0

1

2

3

4

5

6

7

8

9

10

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

1,8

2

[b

a

r]

[m

]

[m

³/h]

Wilo Yonos

Para 15/7.0

FRIWA 30

tube 50 mbar

at Vmax

FRIWA 30

at Vmax

3.4

Corrosion protection

To prevent corrosion damage to plate heat exchangers, the following drinking water values

must be observed:

Maximum permitted drinking water values in conjunction with stainless steel plate heat

exchangers [SS 316/1.4404]

Copper-soldered

Solid stainless steel

Chloride

1

(CL

-

)

< 300 mg/l at 60°C

< 100 mg/l at 80°C

< 300 mg/l at 60°C

< 100 mg/l at 80°C

Sulphate

1

(SO

4

2-

)

< 70 mg/l

< 100 mg/l

Nitrate

(NO

3

-)

< 50 mg/l

pH value

7.5 - 9.0

7.0 - 9.0

Electrical conductivity*

(at 25°C)

10

– 500 µS/cm

Hydrogen carbonate (HCO

3

-

)

70 -300 mg/l

60 -300 mg/l

Ratio HCO

3

-

/SO

4

2-

Ratio > 1.0

Ratio > 1.5

Ammonia (NH

4

+

)

< 2 mg/l

Free chlorine gas

< 1 mg/l

Sulphite

< 1 mg/l

Hydrogen sulphide (H

2

S)

< 0.05 mg/l

Free (aggressive) carbon dioxide

(CO

2

)

< 5 mg/l

Iron (Fe)

< 0.2 mg/l

Aluminium (Al)

< 0.2 mg/l

Manganese (Mn)

< 0.1 mg/l

Degree of hardness

>4.0° dH

1

It is not permitted to use the fresh water station if the limit values are exceeded.

To prevent pitting corrosion in the domestic installation, no new galvanised iron material must

be installed downstream in the hot water pipe of the copper-soldered plate heat exchanger

without forming a protective layer.

Solid stainless steel plate heat exchangers must be used in mixed installations with zinc-

coated iron materials, e.g.

FRIWA 50 VA

with solid stainless steel plate heat exchanger.

Summary of Contents for FRIWA 30

Page 2: ...Deutsch...

Page 19: ...English...