SAB12-0669_02_Installation and Maintenance Manual SFxxx-S

6

6.2 Site Location

Ensure that the maximum wind and snow loads in local conditions do not exceed the SF PV module maximum load

ratings.

Avoid installing SF PV modules in areas exposed to oil vapor and /or corrosive gas.

Avoid accumulation of grit or dust on the SF PV modules as it may influence the output yield.

Do not expose SF PV modules to sulphurous atmospheres.

Do not install SF PV modules in locations where flammable gases accumulate or flow as there is a risk of sparks from

SF PV modules.

Do not install SF PV modules near fire.

Avoid installing SF PV modules in locations where they may be permanently covered by shadows. This may adversely

affect their performance.

Do not install SF PV modules in locations where temperatures exceed the temperature range indicated in the module

’

s

technical specifications.

6.3 Module Handling Instructions

Do not disassemble or modify SF PV modules. This may result in an electric shock, fire or other accidents. Solar

Frontier cannot be held responsible for any loss or damage caused by unauthorized disassembling, modification or

misuse of SF PV modules.

Do not drill additional mounting holes into the aluminum frame. Only pre-drilled holes should be used.

Avoid placing any stress onto the SF PV modules, cables or connectors. (Minimum bending radius of 39 mm or 1.54in

for module cables is recommended)

Do not stand or step on SF PV modules. This may result damage to the module and/or bodily injury by falling.

Do not drop SF PV modules or drop objects onto them. Both sides of the module (the glass surface and the back

sheet) are fragile.

Do not strike the terminal box or pull the cables. The terminal box can crack and break, while the output cable may

unplug and cause electricity leakage or an electric shock.

Do not scratch the backsheet or cables of the SF PV modules. Rubbing or scratching may result in an electric shock,

electric leakage or an accident.

Do not scratch the insulation coating of the frame (except for the grounding connection). This may weaken the strength

of the frame or cause corrosion.

Do not cover the water drain holes of the frame. Doing so may cause frost damage.

Do not use glue when closing the cover of the junction box. Similarly, do not use a sealant to bond the junction box lid

to its base.

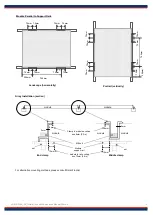

6.4 Module Mounting Instructions

Mounting Structures Cautions

Pay attention to the electrochemical series when selecting support structure material to avoid galvanic corrosion.

Fasten and lock bolts completely. Inadequate mounting may result in SF PV modules to falling or other accidents.

Ensure that the SF PV modules are securely fastened to the mounting support structure that is durable, made of

corrosion and UV resistant material, and follow the applicable local and civil codes.

Ensure that your mounting support structure is designed to withstand the SF PV module design snow and wind loads

applicable for your chosen site. Solar Frontier will not be responsible if the SF PV modules are damage due to the

durability of the mounting support structure. Consult your mounting structure manufacturer for an appropriate

mounting design.

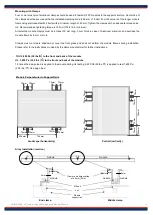

Mounting the Solar Modules

PV modules should typically face South in the Northern Hemisphere and North in the Southern Hemisphere for optimal

power production.

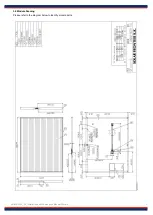

Modules can be installed horizontally (landscape) or vertically (portrait).

When installing, allow for 2 mm or greater spacing between modules.

Maintain a space between SF PV modules and the roof. This will allow air to circulate, cooling the module, and

allowing condensation to dissipate. Solar Frontier recommends a distance of at least 100 mm (3.94 in).

PV modules should be installed over a fire-resistant roof covering.

Summary of Contents for SF135-S

Page 10: ...6 9...

Page 11: ......

Page 14: ...8 9 B B BB 1 BB BB BB ABBB B CCC 1...

Page 18: ......

Page 49: ...SAB12 0669_02_Installation and Maintenance Manual SFxxx S 13...