12

Chapter Four: How to Use the Printer and

the Check Work before/after Use

In this Chapter, you will learn how to use the printer, including check work before and after use.

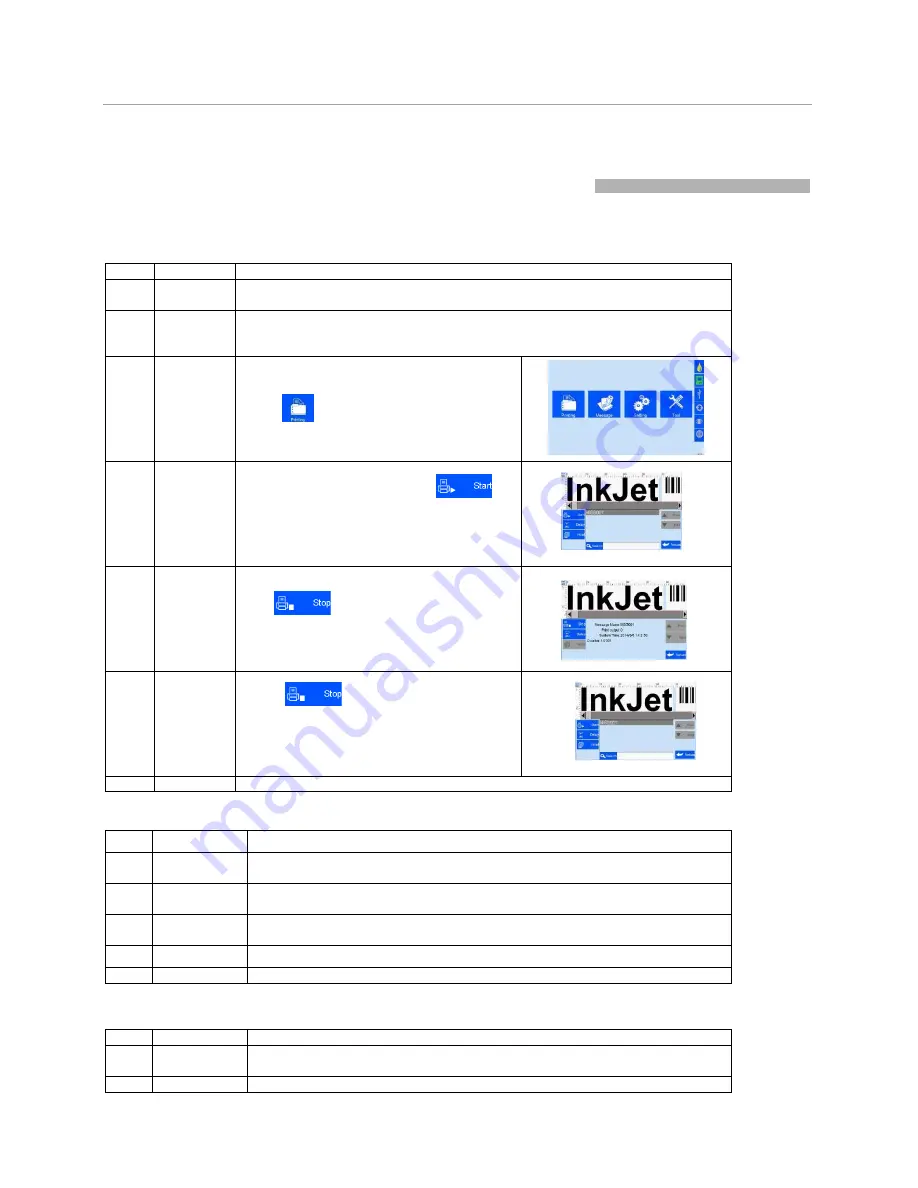

4.1 How to Use the Printer

Sq #

Procedure

Instructions

1

cartridge

Installation

Insert cartridge into the printer stall by an angle of 15 degree, close cartridge clip to

secure. (See Section 2.3 Cartridge Installation).

2

Turn on

printer

Load battery to compartment on printer handle, secure with lock catch (see

Section 2.2.2 Battery Installation and Removal). Switch on power, printer enters

initialization startup.

After initialization startup,

“main interface

Main

appears (see Section 5.1)

Interface -

3

Printing

Manage

m ent

Click

to enter

“Printing Managemen

(see Section 5.2).

4

Select

data - Start

printing

Select a file on data list, click

Start printing.

to

5

Printing

report

When printing starts, the button change to the

icon

for stop printing,

meanwhile a printing report appears.

6

Stop

printing

Click

to stop printing, printing

report exits, and the button returns to

“Sta

printing

” status.

7

Switch off

Exit printing, and switch off power.

4.2 Check Work before Use

Sq #

Item

Check Work

1

Battery

charging

Is the battery fully charged?

2

Positioning

wheels

Do the wheels slide well?

3

Encoder

Is the encoder well connected to positioning wheels? Make sure the connection

is not loose.

4

Cartridge

Is the cartridge wiped clean? Has the cartridge been installed to printer?

5

Printer status

Check status bar, is the equipment status normal?

4.3 Check Work after Use

Sq #

Item

Check Work

1

Printer

Power Status

Is the printer power switched off for power saving?

2

cartridge

Is the cartridge removed from printer and wiped clean and printhead capped?

Summary of Contents for Elfin IC

Page 41: ......