8

11 Pre-start engine inspection

11.1 Checking oil level

!

Check the oil level in the engine,

according to the engine manual

before operating.

!

CAUTION

Running the engine with insufficient

oil level will cause damage and is not

covered by warranty.

V

NOTE*

Automatic engine oil level protection

system will switch off the engine if

the oil level falls below a safe level,

but to ensure the safe operation of

the engine it is recommended to

check the oil level before each trip.

*This function is disabled on

Snowdogs, designated for USA and

Canada.

12 Fueling

!

Fill the gasoline engine according to

the engine manual.

!

NOTE

•

Fuel is highly flammable and explosive, you should avoid

getting burned and injured while working with it.

• Stop the engine before refueling. Make sure there are no

heating appliances, sparks or flames around.

• Refuel only outdoors.

• Refuel only in a well-ventilated area and only if the engine is

stopped. If the engine has been recently running, let it cool

down first.

•

Spilled fuel is not only inflammable, but can also harm the

environment. In case of spilled fuel, wipe down as soon as

possible.

13 Starting the engine

1.

Be sure to follow all of the procedures specified in

paragraph 8.4.

2. Prepare the engine for starting, as described in the

engine manual.

3. Lock the parking brake.

4. Set the engine switch to “ON” position.

If you have an electric starter, press the start button electric

start (no more than 5 seconds) and start the engine.

To use the recoil starter rope, pull the cord slowly, before

resistance, then pull strongly.

When the engine starts, allow it to warm up for 2-5 minutes

After warming up the engine, remove the choke lever. Read

more in the engine manual.

Y

CAUTION

When starting the engine with an

electric starter, do not hold the switch

in “ON” position for more than 5

seconds. If the engine hasn’t started,

you can retry in 10 seconds.

14 Start drive

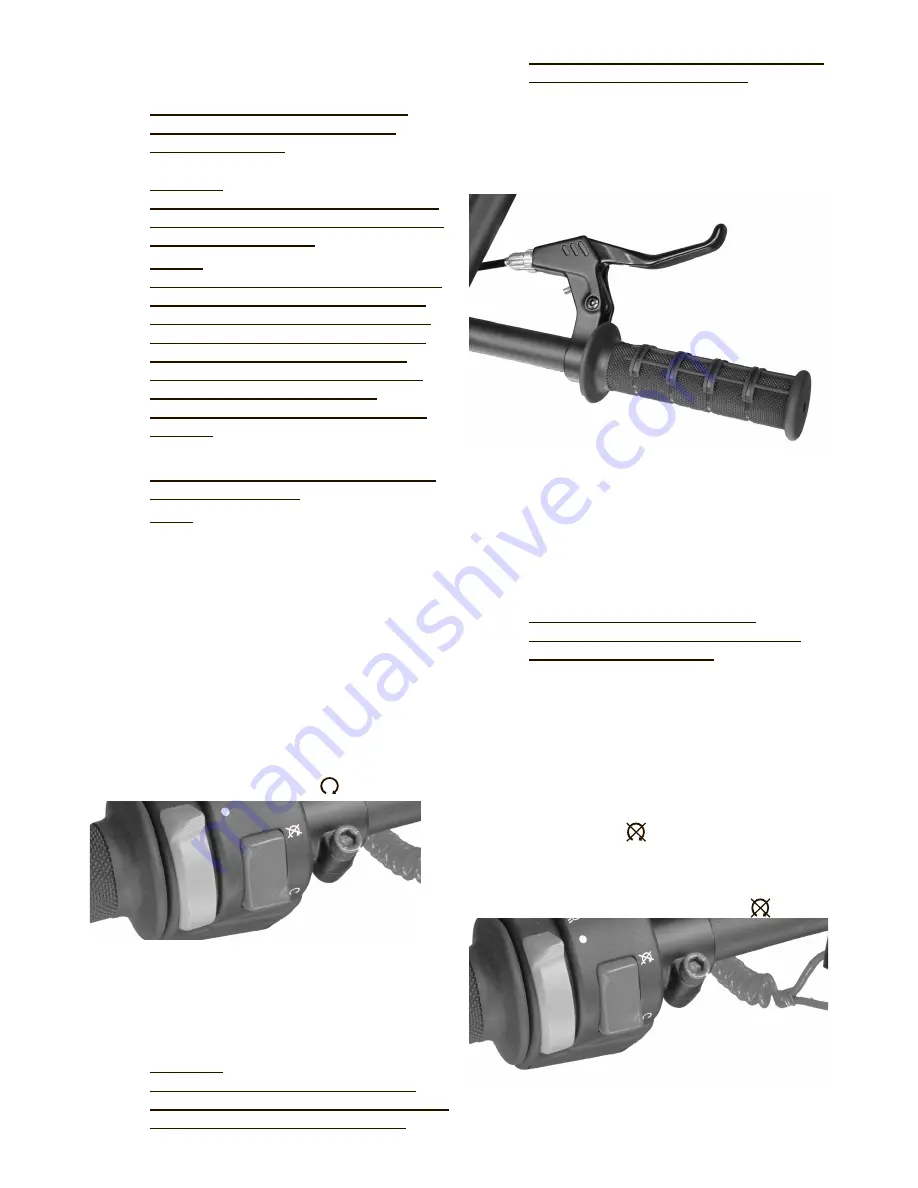

1. Strap the engine security switch on your hand.

2. Release the parking brake.

Slowly squeeze lever to engage the transmission and to start

the SNOWDOG moving. Increase pressure on the throttle lever

until desired speed is reached.

14.1 Automatic engine oil level protection*

This safety system shuts down the engine before the oil level

falls below a safe level. The system will also detect a critical tilt

of the engine and also shut it down. This will prevent possible

damage to the interacting parts working with insufficient

lubrication. Engine switch will remain in “ON” position. If the

engine has stalled and does not start, check the engine oil level

before performing diagnostic study.

V

*This function is disabled on

Snowdogs, designated for in some

states USA and Canada.

14.2 Safety device (if applicable)

The safety device protects the charging circuit of the battery in

case of short circuit or improper connection. When triggered, the

device shows green button switch. Before returning it back into

place, you should locate and eliminate the cause.

To restore the circuit, press the breaker button.

15 Stopping the engine

In case of emergency:

To shut down the engine in case of emergency, turn the engine

stop button switch to “OFF” position. Or pull out the

emergency engine kill switch.

In normal cases:

1. Adjust the throttle lever to lower RPMs .

2. Turn the engine stop butto to switch to “OFF” position.

3. Close the fuel valve (if avalialable)

Summary of Contents for COMPACT B10ZE WL

Page 15: ...15...