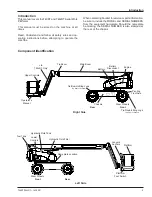

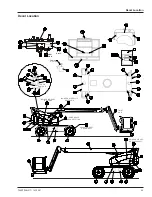

Operation

14

T40RT/T46JRT – 1430001

Operation

The aerial platform may be operated from either the lower

or upper controls.

Danger

The aerial platform is not electrically insulated. Death

or serious injury will result from contact with, or in-

adequate clearance from, an energized conductor.

Do not go closer than the minimum safe approach

distance as defined by national safety regulations.

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components, buildings, structures,

or other obstacles. Make sure there is sufficient clear-

ance around the machine before moving the chassis,

booms, or platform. Allow sufficient room and time

to stop movement to avoid contact with structures

or other hazards.

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over ac-

cident. Operate the aerial platform on a firm, flat, level

surface. Avoid travel speeds and/or rough terrain that

could cause sudden changes in platform position. Do

not drive or position the aerial platform for elevated

use near any drop-off, hole, slope, soft or uneven

ground, or other tip-over hazard.

The platform rated work load is the total weight of the per-

sonnel and equipment that may be lifted in the platform.

The work loads are stated on the platform rating placard

at the:

rear of the platform

lower controls

upper controls

Danger

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over ac-

cident. Do not exceed the capacity values indicated

on the platform rating placard.

Capacity values indicate the rated lifting capacity and do

not indicate aerial platform stability.

The operator bears ultimate responsibility for ensuring

that the aerial platform is properly set up for the particular

conditions encountered.

Cold Weather Start-Up

If the ambient temperature is 0°C (32°F) or below, the

engine and hydraulic system oil may need to be warmed

before operation. Do not operate the engine at more than

a fast idle until the engine and hydraulic oil has had a

chance to warm.

Cold, thick hydraulic oil does not flow well and may cause

delay in response to control movement. Cold hydraulic oil

may also cause cavitation and pump damage.

•

•

•

Hydraulic System Cold Weather Warm-Up

Some machines may have a hydraulic fluid warm-up

system that will automatically warm the fluid upon acti-

vating the warm-up switch. The hydraulic fluid may also

be warmed manually if the machine is not equipped with

the optional warm-up system.

Caution

Not all hydraulic fluid is suitable to use in the hydrau-

lic system. Some have poor lubricating character-

istics and may increase component wear. Only use

hydraulic fluid as recommended.

Use cold weather hydraulic oil as recommended in the

machine General Specifications in temperatures of -12°C

(10°F) or below.

Hydraulic System Warm-Up Switch

This system may be used to warm the hydraulic fluid when

the ambient temperature is below 0°C (32°F) and boom

movement is sluggish because of cold fluid.

There may be a toggle switch for the warm-up system

on the lower control panel and/or one on the front of the

upper control panel.

The engine must be running and the switch used to turn

the system on must be at the same location that the en-

gine was started. For example, if the engine was started

from the lower controls, the warm-up switch at the lower

controls must be used for the system to operate.

To operate the warm-up system:

1. Start the engine.

2. From the same control station that the engine was

started, place the warm-up switch in the on position.

The engine throttle speed will increase while the

warm-up system is on.

3. After the hydraulic fluid has been warmed to operat-

ing temperature and the throttle speed returns to idle,

place the warm-up switch in the off position.

Manually Warming The Hydraulic System

The hydraulic oil may be warmed by bottoming out the

boom extension cylinder. Raise the main boom so it is

horizontal and operate the boom retract function while the

machine is stowed. With the cylinder bottomed out the oil

flow will produce heat to warm the hydraulic oil.

Caution

Not all hydraulic fluid is suitable to use in the hydrau-

lic system. Some have poor lubricating character-

istics and may increase component wear. Only use

hydraulic fluid as recommended.

Use cold weather hydraulic oil as recommended in the

machine General Specifications in temperatures of -12°C

(10°F) or below.

Summary of Contents for 16GTRD

Page 2: ......