9

Section 2 - OPERATING INSTRUCTIONS

2.

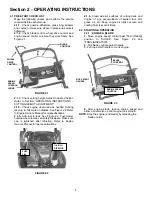

Set all wheels at the same cutting height. The

highest cutting position is Notch 7. The lowest

cutting position is Notch 1. See Figures 2.6 & 2.7.

FIGURE 2.7

2.6 RECYCLING

OPERATION

NOTE:

For best recycling results, cut up to a maximum of 1/3

of grass blade length and recycle ONLY when grass is dry.

1.

Set all wheels in the highest cutting position (Notch

7). Refer to Section “Cutting Height Adjustment”.

2.

Move engine speed control to “FAST” (Rabbit)

position.

3.

Move ground speed control to slowest speed

setting.

4.

Proceed mowing slowly. If grass is very dense,

lower each rear wheel latch one notch lower than the

front wheel latches to improve recycling performance.

NOTE: The recycling cover is designed to remain

on the machine at all times, unless alternate

discharge operations are desired, such as side

discharging or bagging. Recycling cover can be

removed to accommodate alternate discharge

components.

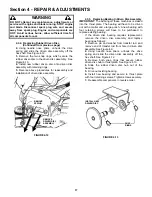

TO REMOVE RECYCLING COVER:

Remove knob nuts and internal/external tooth lock

washers securing rear of recycling cover to mower deck.

Remove cover. See Figure 2.8.

FIGURE 2.8

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP

engine and blade. Disconnect spark plug wire and

secure away from spark plug. Engine and

components are HOT. Avoid serious burns, allow

sufficient time for all components to cool.

2.7 INSTALLATION OF SIDE DISCHARGE

DEFLECTOR

STEP 1:

Remove recycling cover. Refer to Section

“Recycling Operation”.

STEP 2:

Install deflector to deck in place of recycling

cover, making sure that: 1) hole on outside front of

deflector fits onto stud in front of discharge opening where

front of recycling cover was originally installed, 2) slot on

top of deflector slips under restraining nut on top of deck

(under right front corner of engine), and 3) slot on inside

rear of deflector slips onto stud behind rear of discharge

opening, where rear of recycling cover was originally

secured. See Figure 2.9. Install internal/external tooth lock

washers and knob nuts onto studs and tighten securely.

FIGURE 2.9

LATCH

POSITION

CUTTING HEIGHT SETTINGS

FRONT

SLOT

UNDER NUT

REAR SLOT

OVER STUD ;

INSTALL LOCK

WASHER AND

KNOB NUT

FRONT HOLE

OVER STUD;

INSTALL LOCK

WASHER AND

KNOB NUT

REMOVE

KNOB NUTS

AND LOCK

WASHERS

Summary of Contents for RP2167519BDV

Page 23: ...23 PRIMARY MAINTENANCE...

Page 24: ...24 PRIMARY MAINTENANCE...

Page 25: ...25 PRIMARY MAINTENANCE...

Page 26: ...26 PRIMARY MAINTENANCE...