18

Regular Maintenance

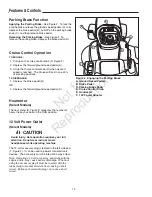

Check & Fill Engine Oil

1. Turn the engine off, and set the parking brake to

PARK.

2. Clean the area around the dip stick (C, Figure 8 or 9).

3. Remove the dip stick (C) and clean it with a paper

towel.

4. Insert the dip stick (C) back into the engine and thread

the cap back onto the tube.

5. Remove the dip stick and read the oil level. The oil

level should be between the “FULL” and “ADD” marks.

If not, add oil according to the oil recommendations

chart (Figure 10).

Figure 9. Briggs & Stratton two cylinder models

A. Oil Drain Valve

B. Oil Filter

C. Dip Stick

A

C

B

Figure 8. Briggs & Stratton single cylinder models

A. Oil Drain Valve

B. Oil Filter

C. Dip Stick

A

C

B

Not

for

Reproduction