5

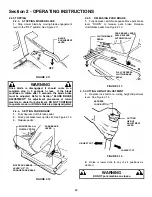

Section 1 - FAMILIARIZATION

FIGURE 1.1

COMPONENTS

The nomenclature drawings above, illustrate the

essential components of the SNAPPER Lawn Tractor. It

is recommended that all operators of this equipment

become thoroughly familiar with the components and

their operation BEFORE OPERATING. Specific details

involving the engine are found in the separate Engine

Owner’s Manual.

Study the Important Safety Instructions, this Operator’s

Manual and Engine Owner’s Manual before operating

this machine. Keep these manuals available for future

reference.

CONTROLS

All operators should be acquainted with the operator’s

controls before attempting start-up or operation of the

Lawn Tractor. See the Control Panel drawing above.

CHOKE

ENGINE

FAST

SLOW

ENGINE

SPEED

CONTROL

KEY

STEERING

WHEEL

DASHBOARD

CONTROLS

FUEL TANK

(UNDER HOOD)

HOOD

OPERATOR’S

SEAT

BATTERY

(UNDER SEAT)

DISCHARGE

DEFLECTOR

MOWING

DECK (33”

SHOWN)

HEADLIGHTS

CLUTCH/BRAKE

PEDAL

DOWN

PARK

BRAKE

LEVER

CONTROL PANEL

CUTTING HEIGHT

ADJUSTMENT

LEVER

SPEED

CONTROL

LEVER

BLADE

ENGAGEMENT

LEVER