21

Maintenance

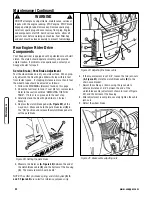

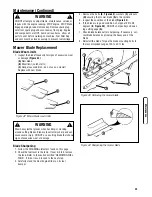

Mower Drive Belt Adjustment

(For 28” & 30” Decks Only)

1. Remove the mower drive belt cover. Refer to the sec-

tion entitled “CHECK MOWER DRIVE BELT”.

2. Move the blade lever up and over to the “ON” position.

3. Place the deck cutting height lever in the third position

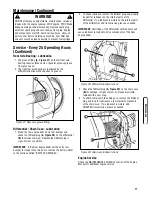

(middle notch). Measure the belt spacing

(B, Figure 36)

between the idler pulley

(A)

and belt. The distance

should measure 1-1/4” but no less than 1”.

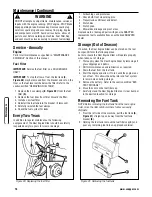

4. If the distance is less than 1”, adjust belt tension:

Move the blade lever to the “OFF” position.

Loosen the hardware

(A, Figure 37)

that secures

the clamp that anchors the front frame assembly

(B)

to the rear main case.

Pull the front frame forward until the belt spacing,

with the blade lever “ON”, measures 1-1/4”.

Retighten the hardware that secures the clamp.

Make sure the hardware is tightened securely.

IMPORTANT:

The SNAPPER Rear Engine Rider Models with

33” decks do not require belt tension adjustment. But, if the

front frame assembly clamp is loosened for any reason,

recheck the belt spacing between the idler pulley and belt.

With the blade lever in the “ON” position, the distance

should measure 1-3/4”.

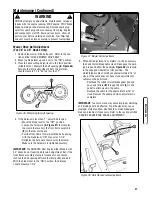

5. When belt adjustment is complete, it will be necessary

to check Clutch/Brake Cable slack. Disengage the park-

ing brake and allow the pedal

(A, Figure 38)

to remain

in the engaged wheel drive (Up) position. The

clutch/brake cable should have approximately 3/16” of

slack. If the cable does not have slack adjustment of

cable must be performed:

Peel back the rubber clutch/brake pedal pad and

push one ferrule

(B)

through the hole

(C)

in the

pedal to attain slack in the cable.

Recheck the cable for the approximate 3/16” of

slack. Replace the pedal pad when adjustment is

complete.

IMPORTANT:

Too much slack may cause improper clutching,

and braking could be affected. Too little slack may cause

improper clutch function. Recheck the service brake/park

brake and readjust if necessary. Refer to the section entitled

“SERVICE BRAKE/PARK BRAKE ADJUSTMENT”.

Maintenance (Continued)

WARNING

DO NOT attempt any adjustments, maintenance, service or

repairs with the engine running. STOP engine. STOP blade.

Engage parking brake. Remove key. Remove spark plug

wire from spark plug and secure away from plug. Engine

and components are HOT. Avoid serious burns, allow all

parts to cool before working on machine. Fuel Filler Cap

and vent must be closed securely to prevent fuel spillage.

!

!

Figure 38: Clutch/brake cable adjustment

C

A

Figure 37: Mower belt adjustment

A

B

Figure 36: Measuring the belt spacing

A

B

B

Summary of Contents for 2811523BV (7084940)

Page 35: ...33 Slope Guide ...

Page 36: ...www snapper com 34 Notes ...

Page 37: ...35 Notes ...

Page 38: ...www snapper com 36 Notes ...

Page 39: ...37 Notes ...