29

Adjustments/Service

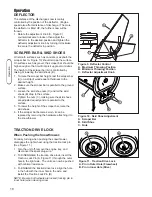

Figure 27. Shear Pins

A. Shear Pins

B. Cotter Pins

A

B

SHEAR PIN REPLACEMENT

Under most circumstances, if the auger strikes an

object which could cause damage to the unit, the

shear pin will break. (This protects the gear box and

other parts from damage.)

The shear pins are located on the auger shaft as

shown in Figure 27. To replace the shear pins, tap

out the broken pin with a pin punch, and install a new

shear pin and cotter pin.

Do NOT replace shear pins

with anything other than the correct grade

replacement shear pin.

(Use of bolts, screws or a

harder shear pin will lead to damaged equipment.)

WARNING

Do not go near the discharge chute or auger

when the engine is running. Do not run the

engine with any cover or guard removed.

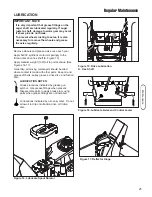

Figure 28. Belt Guide

A. Idler Pulley (Engaged Position)

B. Belt Guide

C. Capscrew

D. Belt

A

1/8” (3.18mm)

C

B

BELT GUIDE ADJUSTMENT

1. Disconnect spark plug wire.

2. Remove screws (B, Figure 25) from belt cover (A).

Remove belt cover (A).

3. Measure the distance between the belt guide (B,

Figure 28) and the belt (D). The distance should

be 1/8 inch (3.18mm).

4. If adjustment is necessary, loosen belt guide

capscrew (C). Move belt guide (B) to correct

position. Tighten capscrew (C).

5. Reinstall belt cover (A, Figure 25) securing with

screws (B).

6. Reconnect spark plug wire.

D

Service

A

B

Summary of Contents for 1695302

Page 23: ...23 Maintenance ...

Page 34: ...34 Adjustments Service Service NOTES ...

Page 36: ...36 Specifications ...