Smoker Assembly

Locate:

• Water Pan Fill Spout

• (8) Grid Supports

Tools Needed:

None

Procedure:

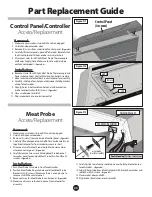

Assemble (4) grid supports in the

holes in the left side of the smoker.

Repeat the procedure for the right

side making sure the grid supports

on the left side and right side are

at the same height so the cooking

grids are level.

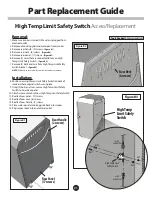

Assemble the water pan fill spout

to the water pan fill door as shown

below.

Grid

Supports

Step 5

Water Pan

Fill Spout

10