6

Where required by the local authorities having jurisdiction, a fuel

cleaning device such as a filter or strainer should be installed in

the main gas supply line to the unit (see Figure 1 on Page 3).

A gas service pressure regulator is required to maintain the

gas supply pressure below the maximum allowable pressure

indicated on the appliance rating plate. A gas pressure relief

valve, if required by the local code authority, should be installed

upstream of all operating and safety controls in the gas train

and downstream of the gas pressure regulator in the gas supply

line (see Figure 1 on Page 3).

Pertinent operating, cleaning and testing procedures are outlined

in this supplement in the TESTING AND MAINTENANCE section.

A Manufacturer’s/Installing Contractor’s Report for ASME CSD -

1 Certification and Reporting (CG-500) requirements is provided

with the instructions. This report shall be made available to

the authorized inspection agency or the inspector for action

as required by the local jurisdiction. Installing contractors shall

maintain a data report for each installation completed. It is the

responsibility of the installing contractor to deliver the pertinent

operating, cleaning and testing procedures together with the

complete wiring and piping diagrams, to the owner/user and to

obtain a receipt for the instructions. The receipt shall be filed with

the installation report.

TESTING AND MAINTENANCE

Periodic testing of all boiler controls and safety devices is

required to verify correct operation. Precautions shall be taken

to protect against bodily injury or property damage while tests

are being conducted. Cover plates that require removal in

order to gain access to items requiring maintenance or testing

shall be replaced before the boiler is put back in service. Since

it is essential to have all control and safety devices operating

as intended at all times, a periodic testing and maintenance

schedule should be set up and followed with results being logged

on a regular basis. Operators or maintenance technicians should

follow the recommended procedures set forth in the instructions

and allow for any additional circumstances that arise based on the

particular installation when preparing a maintenance program.

The operator or technician should thoroughly understand the

operating procedures and be able to recognize an equipment

malfunction. Obtain a receipt for the instructions. The receipt

shall be filed with the installation report.

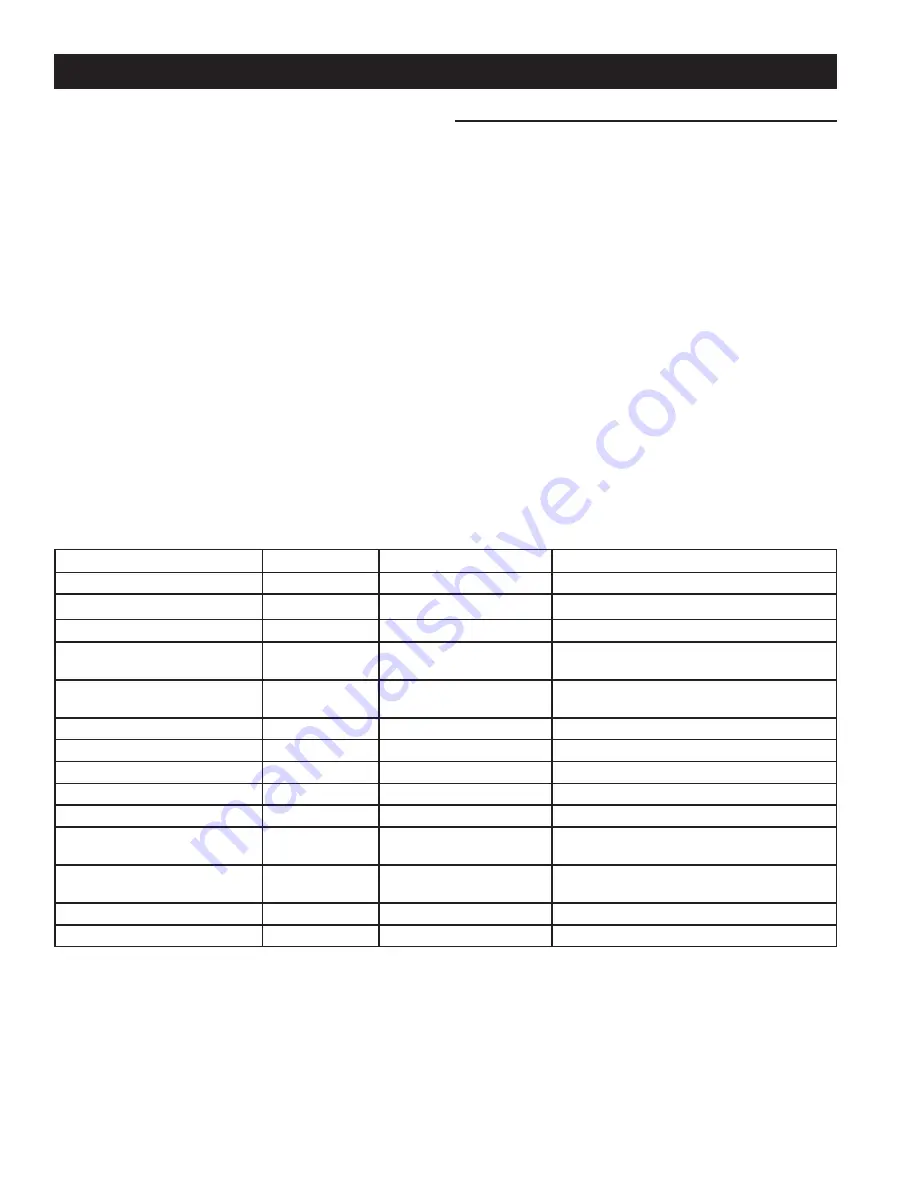

Table 1, provided herein is a recommended guideline to follow

for periodic testing of the boiler's safety devices and controls.

Detailed maintenance procedures are included here as well.

ITEMS

FREQUENCY

ACCOMPLISHED BY

REMARKS

1. Gauges and Indicators

Daily

Operator

Visually inspect, log observations.

2. Burner Flame

Daily

Operator

Visually inspect for uniform blue flames.

3. Pilot Burner

Daily

Operator

Visually inspect for uniform flame envelope.

4. Flame Failure Detection

Weekly

Operator

Close Pilot Manual Shutoff Valve, check

safety shutdown time, log results.

5. Gas Valves

Weekly

Operator

Open Operating Control, listen for valve

closure, check for voltage.

6. Flow Switch

Weekly

Operator

See detailed instructions.

7. Vent System

Monthly

Operator

See detailed instructions.

8. Optional Power Vent

Monthly

Operator

See detailed instructions.

9. Burner Components

Monthly

Service Technician

See Owner’s Manual

10. Heat Exchanger Assembly

Semi-Annually

Service Technician

See detailed instructions.

11. Transformer

Semi-Annually

Service Technician

Check primary and secondary voltage, log

results.

12. Manual Reset High Limit and

Auto Reset High Limit

Annually

Service Technician

See detailed instructions.

13. Safety Valves

As Required

Operator

See detailed instructions.

14. Drip Leg and Gas Strainer

As Required

Operator

See detailed instructions.

TABLE 1. PERIODIC TESTING PROCEDURES

TESTING AND MAINTENANCE