Doc. no.IZ

*

-OMV0005

6

6) Do not allow foreign matter or tool to enter the ionizer nozzle.

The emitter is installed in the nozzle. If conductive objects such as metal tools or the human body either

contacts or comes close to the emitter, reaction to electric shock can lead to further injuries due to collision

with surrounding equipment. Also, if the tool damages the emitters, it may interfere with the specified

function and performance, and may also cause operation failure or an accident.

7) Avoid applying moment to the nozzle.

A moment may be applied to the nozzle depending on the shape or length of the nozzle mounted to the

female threads for piping. It is possible that the nozzle or body will be damaged.

If a moment force of more than 0.05 Nm is applied, the middle of the nozzle should be supported so that the

nozzle does not receive the moment.

8) Do not adhere tape or labels onto the product body.

If the tape or label contains conductive adhesive or reflective paint, it is possible that due to the dielectric

effect, charge could build up causing an electro-static discharge or electrical leakage.

9) Ensure that both the power supply and compressed air supply are disconnected before commencing

with the product installation.

1) Make sure to confirm the effect of static neutralization after installation.

The effect of the static neutralization varies depending on the surrounding installation and operating

conditions. Confirm the effect of the static neutralization after installation.

1) Before wiring, ensure that the power supply capacity meets the specification and that the voltage is

within the specification.

2) To maintain product performance, the power supply should be UL Class 2 certified by National Electric

Code (NEC) or evaluated as a limited power source according to UL60950.

3) To maintain the product performance, ground the product with an earth ground cable with a resistance

of 100 Ω or less according to this manual.

4) Remove the power supply before wiring (including the connector plug in/out).

5) Ensure the safety of wiring and surrounding conditions before supplying power.

6) Do not connect or disconnect the connectors (including power source) while the power is being

supplied. Failure to follow this procedure may cause product malfunction.

7) Malfunctions stemming from noise may occur if the wire is installed in the same route as that of power

or high-voltage cable. Route the Ionizer wires separately.

8) Confirm that there is no error in wiring before operation. Incorrect wiring will lead to product damage or

malfunction.

9) Flush the piping before connecting. Verify that all dust, moisture, oil, etc. are eliminated from the piping

before connecting.

Wiring and Piping

Caution

Warning

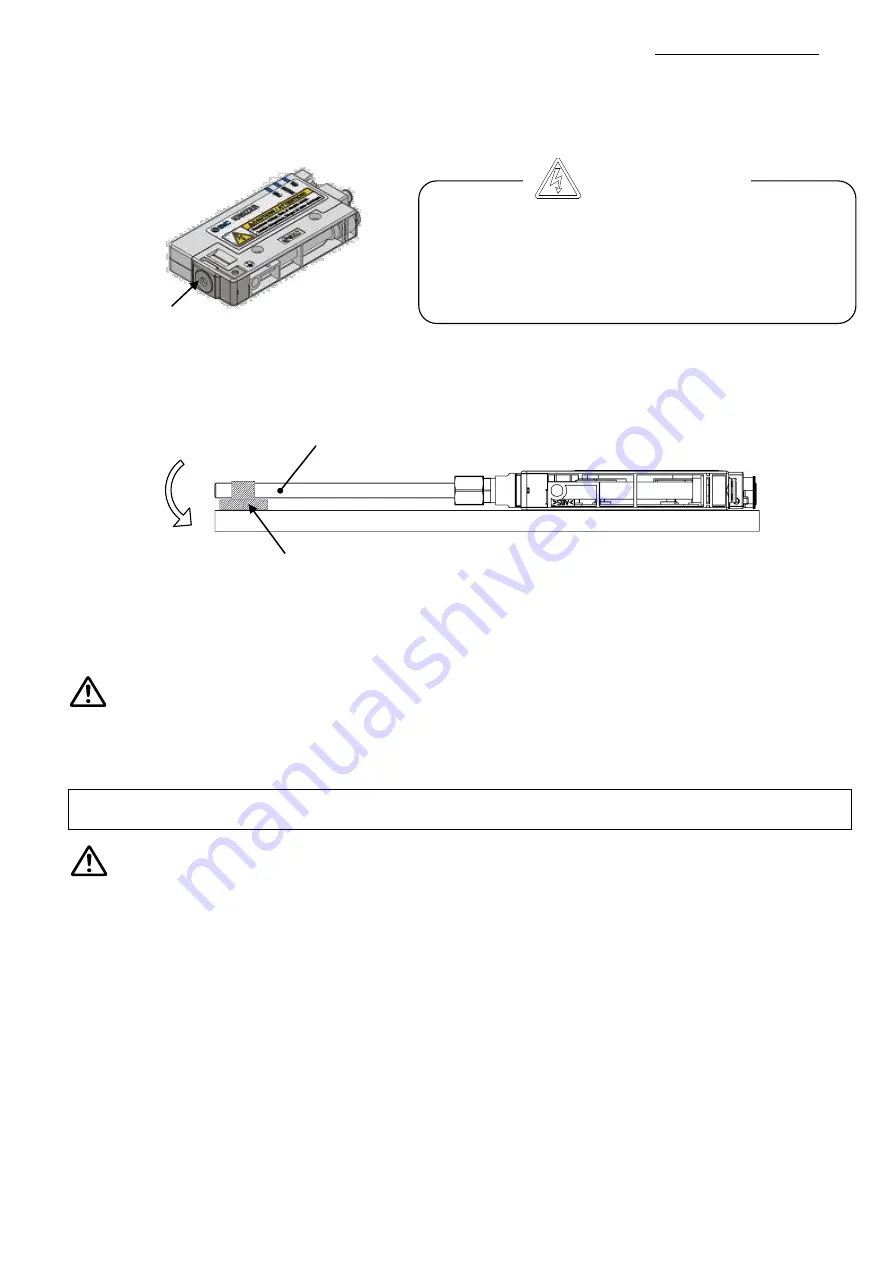

High voltage is applied to the emitters. Never touch the

electrodes. Inserting foreign matter into the cartridge or

touching electrode may cause electrical shock and

instantaneous rapid body motion to escape from the

shock. Your body may then touch the equipment around

you, causing injury.

Danger High voltage

Nozzle

Nozzle

To hold the nozzle

Moment