7) Shorten the piping length.

If piping, too long is connected, the volume of the piping becomes larger than that of the cylinder, and the

mist created by adiabatic swelling is prevented from escaping to the air and remains inside the tube. As

the operation is repeated, the amount of mist is increased and may turn into water. Then, the grease is

washed away by the water and a lack of lubrication, wear of packing, air leakage, friction resistance

increase and operating failure is caused subsequently. To prevent this, the following measure should be

taken.

(1)Shorten the piping tube between solenoid valve and cylinder as much as possible to ensure the

created mist is exhausted to the air. For reference, the following relation should be achieved.

Cylinder content volume at atmospheric pressure×0.7≧Piping tube content volume

(2)Connect speed exhaust controller ASV and quick exhaust valve in the circuit of the cylinder to

exhaust the pressure to atmosphere directly.

(3)Locate the piping port downward to prevent the moisture created in the piping from returning to the

cylinder easily.

8) Give consideration not to splash chemical, which could wash away oil, on the sliding part of

the cylinder.

Some chemicals could wash away the grease from the sliding part of the piston rod. Any chemical other

than general cleaning fluid for water and food could shorten the life significantly. Consult SMC if it is

used.

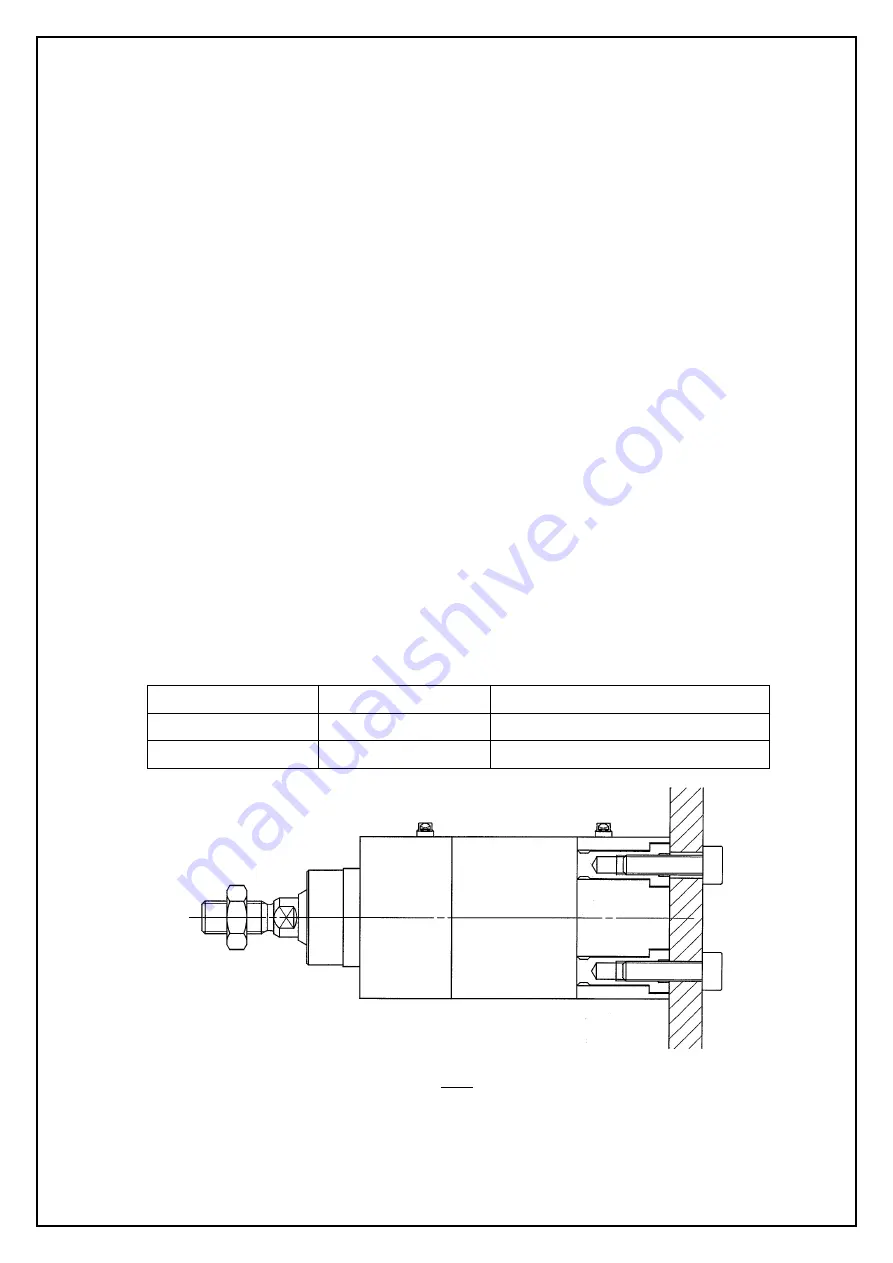

9) Mount the cylinder, support bracket and plug bolt with the following specific tightening

torque.

Table 1

Applicable bore size

Thread size

Tightening torque(N・m)

Φ32・40

M6×1

4.22~7.60

Φ50・63

M8×1.25

10.20~18.40

Fig 2

10) The mounting screw and bracket for the cylinder might let the dust collected in some

operating conditions.

-

10

-

Take a measure depending on the operating conditions when mounting.