LEARN

P/B

MODE

MENU

SET

M1

M2

LEARN

P/B

MODE

MENU

SET

M1

M2

HALL

GND

GND

+5V

(H2)

(–)

(–)

(+)

HALL

GND

GND

+5V

(H2)

(–)

(–)

(+)

-8-

Electrical Connection

WARNING

Do not fix the control box or junction box

upside down. This will cause water and/or condensation

to enter through the cable glands and will void the

warranty.

Motor Connection for Single Leaf Gate

For single leaf gate the opener is prewired ready for set

up. Simply connect the motor connector cable from the

controller to the motor.

Go to page 11 to code transmitters then page 11 for limits

set up procedure.

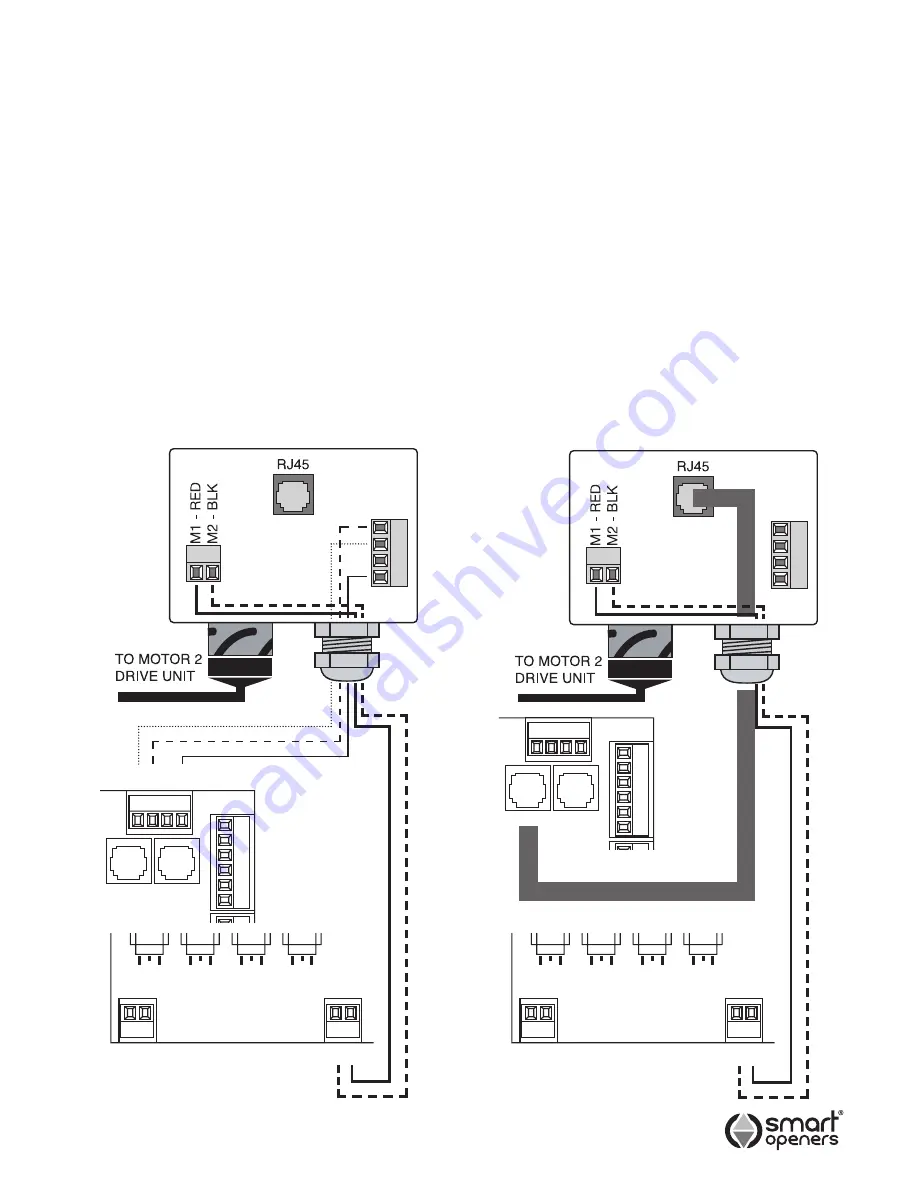

Motor Connection for Two Leaf Gate

For a two leaf gate a junction box is required with

connection via a 5-core cable or 2-core for motor power

plus

RJ45 positioning encoder cable (supplied in your

kit). Ensure that the cable is properly protected with a

cable gland at each end and a suitable conduit across or

under the driveway.

Note:

Motor 1 is the primary opener and opens first. The

leaf that has the trailing edge/overlap is opened by

motor 2. If you need to swap the motors over so

that the overlap is on the same side as the control

box swap the motor and encoder wires over.

Connect 5-core cable from Motor 2 and encoder

terminals in the control box to the Motor 2 Junction Box

as per wiring diagram (Fig. 5).

Alternatively use an RJ45 cable for the encoder

connection as per Fig. 6.

Fig. 5

Fig. 6

LEARN

P/B

MODE

MENU

SET

LEARN

P/B

MODE

MENU

SET

Com

Push Btn

Ped

Stop

Close

Open

Com

Push Btn

Ped

Stop

Close

Open

MOT

OR 2

JUNCTION BOX

MOT

OR 2

JUNCTION BOX

MOTOR CONNECTION

WITH 5-CORE CABLE

MOTOR CONNECTION

WITH RJ45 CABLE

2 1

BLACK

BLACK

RED

RED

2 1

2 1

2 1

- H2 H1 +

Encoder 2 Encoder 1

Encoder 2 Encoder 1

© November 2011 Smart Openers Pty Ltd