244

SJ82 T, SJ86 T

229040ABA

Section 5 – Procedures

Manifolds and Hydraulic Pumps

5.8 Manifolds and Hydraulic

Pumps

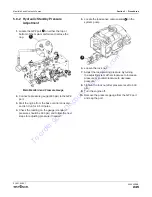

5.8-1 Hydraulic Brake Pressure

Adjustment

Maintaining accurate hydraulic brake pressure is

important when it comes to safe aerial platform

operation.

1.

Locate the pressure gauge

1

on the brake

valve assembly.

IMPORTANT

Failure to remove the wiring may cause damage to

components downstream.

2.

Remove the wiring from two valves: axle lockout

valve

2

wires 65 and 02, and two speed valve

3

wires 45 and 02. Mark the valves to ensure

you put the wiring back in the correct positions

later.

IMPORTANT

Valve damage will occur if tightened too much.

3.

Locate the brake system pressure reducing

valve PR1

4

. Loosen the lock nut and turn the

adjustment stem gently clockwise 2 full turns.

4.

Start the engine from the platform control

console and extend the boom slightly

(approximately 12” (30 cm)) to achieve low

speed drive.

5.

Drive the MEWP forward or reverse. The

pressure gauge reading should be 400 psi. Stop

the aerial platform. Follow the next steps for

adjusting the relief valve pressure if needed. If

no adjustment is required, skip ahead to step 10.

6.

Locate the brake system pressure reducing

valve PR1 and turn the valve gently

counterclockwise to the initial position.

7.

Drive the MEWP forward or reverse. The

pressure gauge reading should be 400 psi.

8.

Stop the MEWP and adjust the pressure

reducing valve PR1 1/4 turn at a time by turning

it either clockwise to increase the pressure, or

counterclockwise to decrease the pressure.

9.

Repeat steps 7 and 8 until the brake pressure is

achieved (400 psi) then tighten the lock nut on

the brake system pressure reducing valve PR1.

10.

Reinstall the wiring in the same positions it was

removed from in step 3.

11.

Test the brake and two speed functions.

2

3

1

4

To

order go

to

Discount-Equipment.com