188

SJ82 T, SJ86 T

229040ABA

Section 5 – Procedures

Boom

5.4-9 Fly Boom Section Removal

1.

On the platform end of the boom, mark and

remove the slave cylinder hoses on the top

side of the fly boom tip. Crack the lines slowly

to relieve any residual pressure. Use a suitable

container or rags to catch any oil spillage. Cap

hoses and ports to keep them clean.

2.

Remove the fasteners for the cable/hose tube

support on the side of the fly boom.

M62253AA

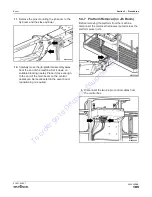

3.

Remove the top and side wear pads and shims

inside the platform end of the mid boom.

Store the shims with their repective parts for

reassembly later.

M62255AA

4.

Place a suitable stand that can bear the weight

of the fly boom ahead of the machine. Attach

a lifting sling to the tip of the fly boom. Lift it up

slightly, then remove the bottom wear pad.

M62256AA

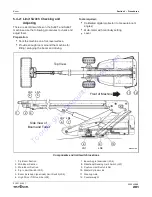

5.

Lift/slide the fly boom out 2/3 of the way. Pull it

out straight to avoid binding. Set it down on the

stand to re-sling as required. Balance the load

as it is being removed.

NOTE

All the wear pads must be removed from the

platform end of the mid boom so the fly boom

section can be pulled all the way out. The wear

pads on the counterweight end of the fly boom

section would otherwise prevent removal.

6.

Slide the fly boom completely out of the mid

boom and set it down on suitable blocking.

7.

Replace the wear pads on the counterweight

end of the fly boom. Use Loctite 242 or 243 on

the wear pad fasteners.

M62257AA

To

order

go

to

Discount-Equipment.com