switch is accidentally bumped when the operator is entering or exiting the skid steer with

the engine running.

Always refer to the polarity symbols printed on the top of the battery. Refer to the

markings on the battery to determine the location of the negative (-) cable. If the battery

cables are to be removed from the battery, always remove the negative cable first and

reinstall the negative cable last.

DO NOT smoke around a battery, or use anything that produces an open flame or spark

to avoid an explosion that could result in Death or Serious Injury.

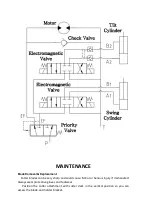

The 12V power source for this attachment should be connected into the skid steer's

Operator Presence System that cuts the electrical power to the attachment shift valves if

the operator safety restraint bar is raised or the seat switch is disengaged when the

operator raises from the seat.

When using the provided joystick, route the electrical harness up to the pivot point of

the loader arm and tie it with plastic cable ties to the inside of the loader arm to prevent

snagging the harness with branches. After installing harness, check that the harness is

free from any tension when raising and lowering the loader arm through its complete

cycle.

To protect the operator from any flying debris, it is important that the skid steer is

equipped with a thermoplastic polycarbonate windshield or similar.